W&H Lexa Mini Maintenance Guide

With the W&H Lexa Mini in the market, you’ll need all the info and instructions you can get your hands on. We have an installation guide, operation guide and a printer management guide already available on our site which you can find on our news tab here. In continuing to provide instructions for the W&H Lexa Mini, this article will cover the Maintenance Guide. Autoclave maintenance is vital to ensuring your autoclave runs properly, and that it’s insured for longevity. This maintenance guide comes straight from the manufacturers over at W&H. And it’ll cover the various maintenance instructions for the W&H Lexa Mini.

our news tab here. In continuing to provide instructions for the W&H Lexa Mini, this article will cover the Maintenance Guide. Autoclave maintenance is vital to ensuring your autoclave runs properly, and that it’s insured for longevity. This maintenance guide comes straight from the manufacturers over at W&H. And it’ll cover the various maintenance instructions for the W&H Lexa Mini.

If you have any questions about the Lexa Mini, autoclaves or anything else, please give us a call at 704-966-1650 Option 3 for our Free Tech Support Line.

Warnings for Maintenance Operations

WARNINGS

WARNING! Turn the sterilizer OFF and remove the power cord before beginning any maintenance. Follow all health, safety, cross-infection and cross-contamination protocols.

Maintenance operation shall be done at illumination level of 215 lx (±15 lx) to 1500 lx (±15 lx).

Before making any operation, ward off unauthorized personnel from the working area.

![]() CAUTION! Before accessing the chamber and the connected parts, be sure that the sterilizer is cold.

CAUTION! Before accessing the chamber and the connected parts, be sure that the sterilizer is cold.

Notice: follow the instructions in this chapter when carrying out any maintenance on the sterilizer.

User Maintenance

Maintenance by the User

| Frequency (1) | Cycles (1) | Operation |

| Monthly | 50 | Cleaning the door gasket and the chamber face side. See "Cleaning the door gasket and the chamber face side" Clean the chamber and trays. See "Cleaning the chamber and the chamber accessories" Cleaning the chamber filter. See "Cleaning the chamber filter" Cleaning the external surfaces of the sterilizer. See "Cleaning the external surfaces of the sterilizer" |

| Yearly (2) | 400 (2) | Replace the HEPA filter. See "400-cycle maintenance" |

| Yearly (2) | 800 (2) | Replace the door gasket. See "Replacing the door gasket" |

1: whichever occurs first.

2: even if the maximum cycle number is not reached, it is recommended to replace the consumable parts every year, or if they appear worn or damaged, or if the filters are clogged or discolored.

EXPIRED MAINTENANCE

The sterilizer monitors the wear of consumables by counting the number of cycles executed since the last replacement.

When the number of cycles is close to the maximum, a pre-alert about the concerned consumable is displayed. Please check that you have the requested spare part available, buy one if not. When the maximum number of cycles has been met, a message to replace the consumable will be displayed.

- Tap the animation icon to see an animated replacement procedure.

- When you have replaced the consumable tap to confirm: the executed cycle counter is reset.

REPLACE THE CONSUMABLE BEFORE THE MAINTENANCE DUE DATE

If you replace the consumables before the request of replacement appears, you should manually reset the counters through the following procedure.

- On the homepage, tap Menu > Maintenance

- Select the consumable you want to replace: a message appears showing the current worked hours of the part.

- Tap the animation icon to see an animated replacement procedure.

- When you have replaced the consumable tap the check mark to confirm: the executed cycle counter is reset.

50-cycle or monthly maintenance

CLEANING THE DOOR GASKET AND THE CHAMBER FACE SIDE

Proceed as follows:

Proceed as follows:

1.) Clean the door gasket and the outer edge of the chamber with a non-abrasive cloth moistened with clean water.

Notice: do not use abrasive products, cutting tools or sharp objects.

2.) Rinse with clean water.

Note: when the seal is new it might be necessary to hold the door gently closed at the sterilization start.

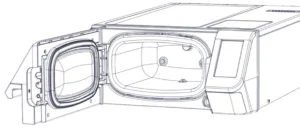

CLEANING THE CHAMBER AND THE CHAMBER ACCESSORIES

Proceed as follows:

Proceed as follows:

- Remove the trays.

- Clean the chamber with a damp sponge and a mild detergent solution paying attention not to bend or damage the temperature probe inside the sterilizer chamber.

- Rinse with water.

- Clean the trays with a damp sponge and a mild detergent solution.

- Rinse with water.

- Reposition all pieces of the chamber accessories properly.

Note: tap the animation icon to see the animated cleaning procedure. Note: the trays may also be cleaned in a washer disinfector.

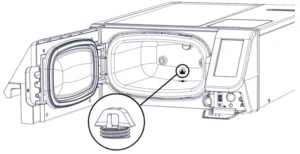

CLEANING THE CHAMBER FILTER

Proceed as follows:

Proceed as follows:

- Allow the sterilization chamber to cool down.

- Empty the sterilizer chamber by removing the trays.

- Remove the filter at the bottom of the chamber by unscrewing it.

- Rinse the filters with tap water.

- Insert the filter in its original position, screwing it into place.

Note: tap the animation icon to see the animated cleaning procedure.

CLEANING THE EXTERNAL SURFACES OF THE STERILIZER

Proceed as follows:

Clean all external sterilizer covers with a slightly damp cloth moistened with water. For better cleaning results, clean with W&H MC-1000 cleaning solution. Note: for cleaning operations, do not dilute the W&H MC-1000 cleaning solution. Notice: never use any other disinfectant, detergent or abrasive product, as they might result aggressive for the external covers and damage them.

400-cycle maintenance

REPLACING THE HEPA FILTER

Notice: the HEPA filter needs to be replaced every 400 sterilization cycles or once a year, whichever come first. A replacement message alerts when replacement is due. If the consumables is replaced prior to the message, you have to reset the consumable cycle counter.

Proceed as follows:

- Unscrew the HEPA filter by hand (counter-clockwise).

- Screw on the new HEPA filter (clockwise) and tighten it snug.

Note: tap the animation icon to see the animated replacement procedure.

800-cycle or yearly maintenance

REPLACING THE DOOR GASKET

Notice: the door gasket needs to be replaced every 800 sterilization cycles or once a year, whichever come first. A replacement message alerts when replacement is due. If the consumable is replaced prior to the message, you have to reset the consumable cycle counter.

Proceed as follows:

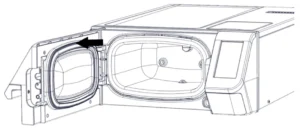

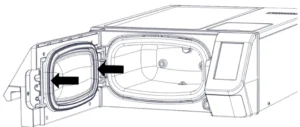

1.) Open the chamber door.

2.) Remove the used door gasket by hand.

3.) Carefully clean the seal seat and the inside face of the chamber door.

Note: tap the animation icon to see the animated replacement procedure.

4.) Insert the new seal and press it starting from the central-upper point.

5.) Press left and right.

6.) Make sure the door gasket is seated evenly.

Extraordinary maintenance

DRAINING THE CLEAN WATER TANK

If you accidently left the tanks full for more than seven days, or if you plan not to use the sterilizer for at least seven days, you have to drain the clean water tank.

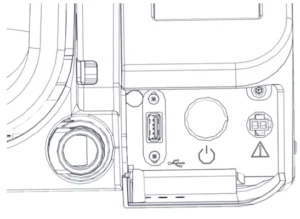

- Open the chamber door.

- Put a container below the sterilizer (0.16 gal (0.6 l) minimum) and place the end of the drain tube in it.

- To drain the water, insert the drain tube connector in the blue connection.

- When the water has been completely drained, press the release button to remove the drain tube and close the chamber door.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

The W&H Lexa Mini Installation Guide is available here on our website.

The W&H Lexa Mini Operation Guide is available here on our website.

The W&H Lexa Mini Printer Management Guide is available here on our website.