Tuttnauer 2340M Installation Guide

The Tuttnauer 2340M offers a compelling blend of simplicity and reliability, making it a favored choice for many healthcare settings. Its straightforward manual operation, coupled with robust safety features, ensures consistent sterilization performance. This dependable autoclave provides a sense of security, allowing practitioners to focus on patient care without worrying about complex procedures. Its enduring design and ease of use contribute to a seamless integration into any practice.

straightforward manual operation, coupled with robust safety features, ensures consistent sterilization performance. This dependable autoclave provides a sense of security, allowing practitioners to focus on patient care without worrying about complex procedures. Its enduring design and ease of use contribute to a seamless integration into any practice.

And here at Sterilizer Autoclave Solutions, we make it our job to provide you with the proper knowledge to make sure everything goes smoothly. So in this article, we’d like to go over the installation instructions for the Tuttnauer 2340M steam sterilizer, with instructions provided by the manufacturer, Tuttnauer.

If you have any questions about the Tuttnauer 2340M or anything else, please give us a call at 704-966-1650 Option 3 for our Free Tech Support line.

Installation Guide

Caution:

The sterilizer must be placed on a rigid and leveled surface. The stand must be able to hold the load of the device and loaded material.

Note:

Make sure, when placing the autoclave, to leave space around the machine, to give the technician access to service the machine.

Electrical

The electrical connection should comply with the devices power requirement. It must also comply with local installation and safety rules and regulations. The voltage supplied to the device must comply with the label ± 5%.

In order to avoid any injury by electrical hazard, it is mandatory for the customer to have installed an earth leakage relay (GFI outlet or circuit breaker) in the electrical circuit to which the autoclave is connected. This relay disconnects all the poles of the electrical power line in case of accidental contact by the power line, with the autoclave’s metal enclosure.

Note: Keep the back and the right side of the autoclave approximately 1” (25mm) away from the wall to allow for ventilation.

Connect the power cord to the socket on the rear side of the autoclave; plug it into the supply outlet.

Setup

Proper adjustment of the chamber pitch is one of the most important things you can do for the sterilizer. Proper chamber pitch insures that among other things, the sterilizer will have the proper amount of water in the chamber at the beginning of each cycle. Insufficient water in the chamber, at the beginning of the cycle, will cause the unit to overheat and activate one of the safety thermostats. This will occur at some point during the cycle when the water level becomes too low. If, on the other hand, there is too much water in the chamber, this will extend the heating portion of the cycle. Extending the heat up time will shorten the sterilization time, causing items to not be sterilized, indicator strips to not change color and spore tests to fail.

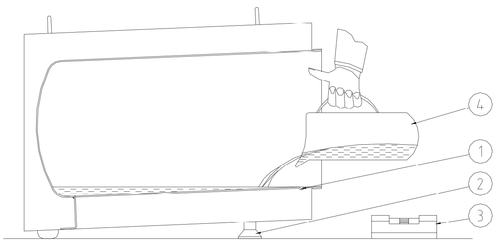

For proper setup please follow these setup steps (see drawing below):

- The autoclave should be turned off and unplugged.

- Make sure the counter is level and sturdy (3).

- Make sure all the feet are on the autoclave and none have been lost.

- Make sure the feet are free to move in and out (2).

- Position the autoclave on the counter.

- Fill the reservoir with distilled water (see sec 7.2).

- The chamber should be empty of any instruments, trays or leftover water.

- The chamber pitch now needs to be adjusted.

- Measure to the proper amount of distilled water for the appropriate model unit as listed below.

1730 2340/2540 3140 3850 3870

10-12 oz (300-350 ml) 12-15 oz (350-450 ml) 14-16 oz (420-480 ml) 20-23 oz (600-690 ml) 24-27 oz (720-810 ml)

- Pour the proper amount of water into the chamber through the front door of the unit (4).

- This water should cover the bottom of the chamber to within +/- 1⁄2 inch of the groove in the front (1).

- If necessary, adjust the front leveling feet, up or down, so that the water lays in the chamber correctly (2).

- Once the chamber pitch adjustment is completed, the unit is ready to operate.

Note: It is imperative to have the correct amount of water in the chamber each cycle for proper operation of the autoclave.

Lifting and Carrying

Caution:

Before moving the autoclave, make sure that the electric cord is disconnected from the power and there is no pressure in the chamber.

- Disconnect the power supply cord.

- Drain the water from the reservoir and vessel.

To avoid injuries, lifting and carrying should be done by two people.

Do not drop this device!

WATER QUALITY

WATER QUALITY

The distilled or mineral free water supplied to the autoclave should have the physical characteristics and maximum acceptable level of contaminants indicated in the table below:

Physical Characteristics and Maximum acceptable contaminants levels in steam for sterilizers

(According to EN 13060:2004).

Element Condensate – allowable content

Silicium oxide. SiO2 ≤0.1 mg/kg

Iron ≤0.1 mg/kg

Cadmium ≤0.005 mg/kg

Lead ≤0.05 mg/kg

Rest of metals except iron, cadmium, lead ≤0.1 mg/kg

Chloride (Cl) ≤0.1 mg/kg

Phosphate (P2O5) ≤0.1 mg/kg

Conductivity (at 20°C) ≤3 μs/cm

pH value (degree of acidity) 5 to 7

Appearance Colorless clean without sediment

Hardness (Σ Ions of alkaline earth) ≤0.02 mmol/l

Compliance with the above data should be tested in accordance with acknowledged analytical methods, by an authorized laboratory.

Attention:

We recommend testing the water quality once a month. The use of water for autoclaves that does not comply with the table above may have severe impact on the working life of the sterilizer and can invalidate the manufacturer’s warranty.

PREPARATION BEFORE STERILIZATION

The purpose of packaging and wrapping items for sterilization is to provide an effective barrier against contamination during storage, once the items have been sterilized.

VERY IMPORTANT!

When sterilizing cotton wool or pads, it is essential to wrap them in paper or cotton bags in order to prevent the multi-purpose valve and the autoclave openings from becoming clogged with remnants of the material.

Packaging and wrapping materials should be approved for use in a steam sterilizer and permit the removal of air and penetration of the steam during the sterilization process.

The basic principle of determining the size, mass and contents of instrument and hollowware packs is that the contents are sterile and dry immediately upon completion of the drying cycle.

Instruments to be sterilized must be clean and free from any residual matter, such as debris, blood, pads or any other material. Such substances may cause damage to the instruments themselves or the sterilizer.

1.) Clean instruments immediately after use. It is recommended that instruments be ultrasonically cleaned in a Tuttnauer Clean and Simple Ultrasonic Cleaner, using Tuttnauer Clean and Simple enzymatic cleaning solution.

2.) After ultrasonic cleaning, rinse under tap water for 30 seconds and pat dry to remove residual minerals. If your tap water has a high mineral content, rinse a second time in a bath of distilled water and pat dry.

3.) Launder textile wraps prior to reuse, but do not use bleach.

4.) Follow the instrument manufacturer’s instructions for cleaning and lubricating instruments.

5.) Be sure that instruments of dissimilar metal (stainless steel, carbon steel, etc.) are separated. Carbon steel instruments should be bagged or placed on autoclavable towels and not directly on stainless steel trays. (Mixing will result in the oxidation of these metals).

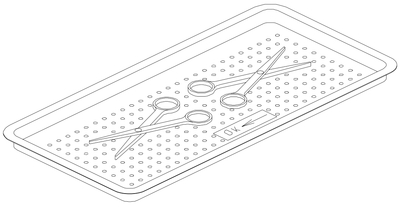

6.) Load items within the boundaries of the tray so that they do not touch the chamber walls, or fall off when the tray is inserted into the autoclave. The chamber walls are very hot; items that come into contact with the wall can be damaged

7.) Check the manufacture’s instructions as to the proper procedure for sterilizing each item. The instrument manufacturer can give specific information on proper sterilization temperature and sterilization time for any item.

8.) Place a sterilization indicator in each tray or inside each wrapped pack.

9.) When using a paper / plastic bag, the plastic side should always be down. Use single-use wraps once only and discard after use.

10.) Verify that the packaging method is in accordance with good practice approach and the packaging materials are in accordance with the applicable standards (e.g. EN868 series).

11.) At least once per week use a biological spore test (Bacillus Stearothermophilus) in any load to insure proper sterilization. (Be aware testing standards may vary).

12.) All instruments must be sterilized in an open position. Place instruments with ratchets opened and unlocked or clipped on the first ratchet position. Surfaces that are hidden because the item is in a closed position will not be exposed to the steam and will not be sterilized.

13.) Disassemble or sufficiently loosen multiple-part instruments prior to packaging to permit the sterilizing agent to come into contact with all parts of the instrument.

14.) Make sure that all instruments remain apart during the sterilization process. Surfaces that are hidden because items are covering other items will not be exposed to the steam and will not be sterilized.

15.) Items prone to trapping air or moisture, e.g. hollowware, should be tilted on edge. This will allow a minimal resistance to the removal of air or condensate during sterilization and drying.

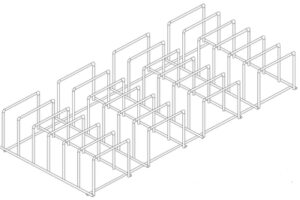

16.) The operator may use racks to allow for adequate separation of packaged instruments.

17.) Do not overload the sterilizer trays. Overloading will cause inadequate sterilization and poor drying. Load trays loosely to capacity. Instruments should be loaded one level deep only. See table in section 2 for recommended loading capacities.

18.) Tubing should be rinsed after cleaning. When placed in the tray, make sure that both ends of the tubing are open and there are no sharp bends or twists.

19.) Empty canisters should be placed upside-down, in order to prevent accumulation of water.

20.) Allow a distance of approximately 1” (2.5 cm) between trays or cassettes to permit steam circulation.

21.) Wrapped instruments should be packed in material which will allow steam penetration and promote drying, such as autoclave bag, autoclave paper, or muslin towels.

22.) Do not stack pouches.

It is recommended that a Tuttnauer™ Pouch Rack be used. This will allow the operator to place pouches on their side, which will increase capacity and will allow for better exposure to steam for sterilization and better circulation of air for drying.

23.) If spotting is detected on the instruments, the first step would be to use an ordinary eraser to remove the spot. If there is no pitting under the spot, the spot was only dirt. Dirt spots on an instrument may be an indication that the autoclave needs to be cleaned or that the instruments were not adequately cleaned or dried. If removal of the spot reveals pitting, the spot was most likely rust. Rust spots on an instrument are not uncommon on inexpensive instruments. It may also be an indication that the instruments were rinsed in tap water with a high content of minerals. These minerals when exposed to high temperature and steam will accelerate the oxidation of the metal. One suggestion would be to final rinse the instruments in distilled water.

24.)If the instruments exhibit a discoloration, this can be due to the mixing of carbon steel and stainless steel. When these two metals come into contact with each other electrolysis occurs that breaks down the metal. The best solution is to separately wrap the carbon steel to insulate it from other instruments or the trays.

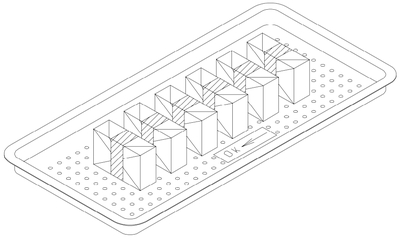

25.) Packs

VERY IMPORTANT!

When sterilizing cotton wool or pads, it is essential to wrap them in paper or cotton bags in order to prevent the multi-purpose valve and the autoclave openings from becoming clogged with remnants of the material.

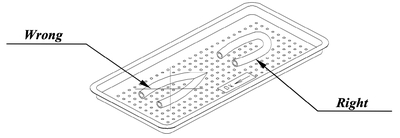

Place packs upright on trays, side by side.

Place packs upright on trays, side by side. - Packs should not touch the chamber walls.

- Pack instrument sets in a manner that prevents damage to delicate items.

- Pack hollowware sets so that all openings face the same direction and so that the contents cannot move inside the pack.

- Load packs of folded operating room drapes with layers vertical, allowing air to be removed from the packs rapidly.

- Do not place packs of hollowware and trays of instruments above textile packs or soft goods in order to avoid wetting caused by condensation from items above.

- Load items packed in flexible packaging materials on edge with paper to laminate, or flat with the plastic surface downwards.

Note: The instrument manufacturer’s recommendations shall be observed, concerning the sterilization data for each type of material.

26.) Tubing

- When placing in a tray, make sure that both ends are open, without sharp bends or twists.

27.) Cassettes

- Instruments may be sterilized in cassettes. The advantage of the cassettes is that the sterilized instruments may remain organized in the cassettes ready for use, while stored in a sterile area.

- If using models 2340 / 2540, remove the trays and slide the cassettes into the chamber on the rack system.

- If using models 3850 / 3870, place the cassettes directly on the tray, either lying flat (but no stacking) or on edge.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

The Tuttnauer 2340M is available here on our website.

We have an introduction to the Tuttnauer 2340M steam sterilizer blog on our website here.