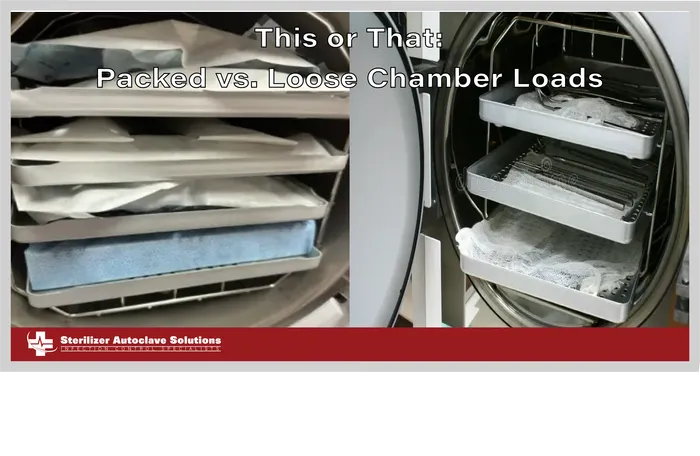

This or That: Packed vs Loose Chamber Loads

Achieving effective sterilization in any autoclave is paramount for patient safety and infection control. One of the most critical factors influencing a sterilizer’s performance is how items are loaded inside the chamber. This guide will clarify the vital differences between packed loads and loose loads, revealing why proper autoclave loading techniques are essential for every healthcare professional, dental clinic, and medical facility. Understanding these best practices ensures your medical instruments are reliably sterile every single time.

So in this article, we’ll help you understand the differences, and lay out some pros and cons of each.

What are Packed Autoclave Chamber Loads?

A packed autoclave chamber load (shown right) occurs when the sterilizer is filled to its absolute maximum capacity, with surgical instruments or other supplies arranged very closely, stacked, or even touching each other. While the immediate goal might be to seemingly increase throughput by processing more items in a single cycle, this common but risky practice significantly hinders proper steam circulation. This method is widely discouraged in professional settings due to its inherent risks to sterilization efficacy.

more items in a single cycle, this common but risky practice significantly hinders proper steam circulation. This method is widely discouraged in professional settings due to its inherent risks to sterilization efficacy.

Pros (Perceived, but Not Recommended):

- Attempted Higher Throughput: Users might try to process more medical instruments in one cycle, aiming to boost perceived efficiency and save time.

Cons (Significant Risks to Sterility):

- Impaired Steam Penetration: Overloading severely obstructs the flow of saturated steam, creating critical “cold spots” where essential sterilization conditions are not met, leading to non-sterile outcomes.

- Increased Risk of Sterilization Failure: Inadequate steam contact means items may not achieve complete sterility, directly jeopardizing patient safety through contaminated instruments.

- Poor Drying Results (Wet Packs): Dense loads trap moisture, making proper instrument drying extremely difficult. Wet packs can compromise sterility upon removal, creating pathways for re-contamination and compromising the sterile barrier system.

- Longer Cycle Times (Potentially): Autoclaves may require extended cycles to compensate for poor steam penetration, or the machine could abort the cycle if it fails to reach required sterilization parameters.

- Difficulty with Air Removal: Trapped air pockets within tightly packed items can prevent steam from properly contacting instrument surfaces and transferring heat effectively, leading to ineffective sterilization.

What are Loose Autoclave Chamber Loads?

A loose autoclave chamber load involves meticulously arranging sterilization items with ample, intentional space between them. This recommended loading technique typically uses appropriate sterilization containers, instrument racks, or pouches designed to ensure proper spacing, preventing items from touching or blocking steam pathways. This method is crucial for facilitating the unobstructed circulation of saturated steam and efficient air removal from the autoclave chamber. It ensures that steam reaches all surfaces of every item, even complex or porous materials, optimizing sterilization efficacy.

Pros (Essential for Effective Sterilization):

- Optimal Steam Penetration: Ample spacing ensures saturated steam can circulate freely around every surgical instrument, reaching all surfaces for thorough and effective sterilization.

- High Sterilization Assurance: Proper loading techniques significantly maximize the chance that all items achieve the necessary temperature and exposure time for a validated sterilization cycle, ensuring infection control.

- Improved Drying: Free circulation of air and steam facilitates efficient instrument drying, greatly reducing the occurrence of “wet packs” and thereby maintaining sterility post-cycle.

- Reduced Risk of Cycle Abortions: With proper steam penetration and air removal, the autoclave is much more likely to successfully complete its sterilization cycle without errors or interruptions.

- Extended Instrument Lifespan: Proper steam exposure and thorough drying minimize residue buildup and corrosion, contributing to the longevity of valuable medical instruments and equipment.

Cons (Operational Considerations):

- Lower Throughput (Per Cycle): Fewer instruments can be processed in each individual cycle compared to an overloaded chamber.

- More Frequent Cycles (Potentially): Busy healthcare practices or dental offices might need to run the autoclave more often throughout the day to meet the demand for sterilized instruments.

Final Thoughts

Ultimately, the decision between packed and loose autoclave loads isn’t merely about expediting workflow; it’s fundamentally about uncompromising patient safety and infection prevention. While the allure of packed loads might tempt facilities aiming for perceived throughput gains, the documented risks of sterilization failure and wet packs far outweigh any minor time savings. Adopting loose loading techniques is the only validated method to ensure every surgical instrument is truly sterile, protecting both patients and staff. Prioritize these autoclave best practices in your sterilization department to achieve consistent, reliable results and uphold the highest standards of care.

So if you have any questions about proper autoclave loading, autoclaves in general, or anything else, give us a call at 704-966-1650 Option 3 for our Free Tech Support Line. You can also find our wide variety of programs available to anyone, anytime, absolutely FREE using the links below.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.