Tuttnauer Tiva 8-MD Maintenance Guide

In this article, we’ll go over the maintenance necessary to maintain your Tuttnauer Tiva 8-MD properly. And if you have any questions, you can give us a call on our Free Tech Support line at 704-966-1650, option 3 for tech support.

Maintenance

General Information

Maintenance is a set of periodic and predefined operations aimed at maintaining the machine functionality in all its aspects as a result of intrinsic wear and use.

It should be remembered that the lower operating cost and a long life of the machine depend on the continuous observance of what is reported in this manual.

WARNING! The washer disinfector maintenance operations must be carried out with the machine completely switched off.

WARNING! If the machine is not used for more than 24 hours it is necessary to run a “Regular” washing cycle, without any instrument inside.

The routine maintenance operations and the frequency of maintenance are described in the Maintenance Logbook.

The Maintenance Logbook is an integral part of this manual. if the Maintenance Logbook is missing, contact your dealer or distributor.

WARNING! it is the user’s obligation to fill in and keep updated the Maintenance Logbook. The incorrect or incomplete compilation of the Maintenance Logbook will void the warranty.

Periodic Maintenance Request

After a certain time or a certain number of operating hours, the display shows «MAINTENANCE». This signal has no influence on the machine operation, contact the customer service or the dedicated technical assistance for periodic maintenance.

WARNING! Periodic maintenance is carried out by the technician under guarantee only if the utilizer has correctly and regularly carried out all ordinary maintenance operations and if the utilizer has filled out and kept up-to- date the Maintenance Logbook.

Personal Protective Equipment (PPE)

The operator engaged in this type of intervention must wear PPE and must be sure that no other unauthorized person is present in the operating area of the machine. Before maintenance, start a program to wash the washing chamber.

Cleaning Products

Clean the outside of the machine with products suitable for stainless steel, glass and plastic materials.

HAZARD! Products unsuitable for cleaning stainless steel, glass and plastic materials may irreparably damage non- interchangeable parts of the appliance and render the machine unusable.

If a suitable cleaning liquid is not available, a mixture of water (75%) and alcohol (25%) may be used. Cleaning should be carried out with a smooth (non-scratchy) cloth moistened with the appropriate liquid.

WARNING! Do not spray the machine or near it with water jets, or with pressure devices.

HAZARD! DO NOT SOAK THE CLOTH to prevent excess liquid from entering electrically hazardous areas for the operator.

The keypad and display should be cleaned with a mixture of water and alcohol or with mild detergents. For cleaning the washing chamber, start a rinsing cycle without instruments.

WARNING! Do not use steel wool, steel brushes, bleach (bleach cause the oxidation of the stainless steel surface and consequent change of color) or any cleaning agent containing bleach or anything abrasive to cleaning the device. Doing so will damage the device!

Routine Maintenance

Routine maintenance operations are performed by the user and includes all those jobs needed to keep the machine clean and functioning. It is mandatory to perform these operations regularly or when necessary and the user is responsible for verifying their regularity. For routine maintenance operations refer to the Maintenance Logbook provided in the machine’s pack.

WARNING! it is the user’s obligation to fill in the Maintenance Logbook correctly and regularly. The incorrect or incomplete compilation of the Maintenance Logbook will void the warranty.

Cleaning the Chamber Filters

Proceed as follows to clean the filters in the wash chamber:

1) Open the door and remove the load rack.

HAZARD! Very hot surfaces

HAZARD! Risk of injury: Be careful with sharp and pointed objects, which are withheld in the racks.

2) Remove the central filter (1 Fig. 11).

3) Remove the mesh filter (2 Fig. 11).

4) Remove the chamber bottom filter (3 Fig. 11).

5) Carefully clean the filters and remove the residual substances.

6) Remove the deposits from the drain and clean the drain.

7) At the end of the cleaning operations, refit the filters in succession.

WARNING! It is mandatory to record the weekly chamber filters cleaning in the Maintenance Logbook. Daily cleaning is also recommended to ensure continuous optimal operation.

Cleaning the Spray Arms

Clean the spray arms as follows:

1) Open the door and remove the load supports.

HAZARD! Very hot surfaces.

2) Loosen and remove both spray arms.

3) Rinse the spray arms thoroughly.

4) Reassemble and tighten in position the spray arms.

WARNING! It is mandatory to record the weekly spray arms cleaning in the Maintenance Logbook. Daily cleaning is also recommended to ensure continuous optimal operation.

Cleaning the Air Suction Filter

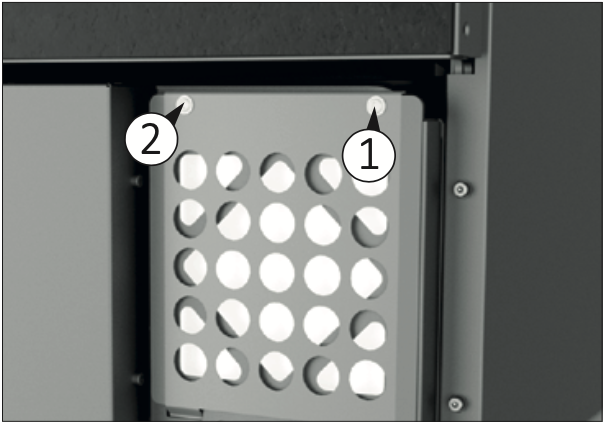

1) Remove the filter cover panel

2) Unscrew the screws (1 and 2 shown above) using a Torx screwdriver T20.

3) Pull out the pre-filter.

4) Clean the pre-filter with compressed air or cold water and dry the pre-filter completely.

WARNING! Reassemble the pre-filter only once it is completely dry. If it is not completely dry it can damage the device.

5) Reassemble the completely dry pre-filter.

6) Retighten the screws and refit the filter cover panel.

WARNING! It is mandatory to record the monthly air suction filter cleaning in the Maintenance Logbook, to ensure continuous optimal operation.

Replacing the Air Suction Filter

The washer disinfector is standard equipped with a suction filter for drying air.

The machine is also standard equipped with an «absolute» «HEPA H14» class supplementary air filter, in compliance with EN 1822.

WARNING! It is mandatory to replace the pre-filter and the HEPA H14 filter as indicated in the Maintenance Logbook. In case of intensive use of the machine it is recommended to increase the frequency of maintenance.

When replacing the air suction filter use a Torx screwdriver T20 to open the filter panel.

Special Maintenance

Special maintenance operations are not foreseen by the user but must be performed exclusively by the technical assistance or by an authorized and qualified service personnel that must refers to the Service Manual.

How to carry out special maintenance operations and the frequency of maintenance are described in the Service Manual.

Contact the Manufacturer service for special maintenance.

WARNING! Special maintenance is carried out by the technician under guarantee only if the utilizer has correctly and regularly carried out all ordinary maintenance operations and if the utilizer has filled out and kept up-to- date the Maintenance Logbook.

Troubleshooting

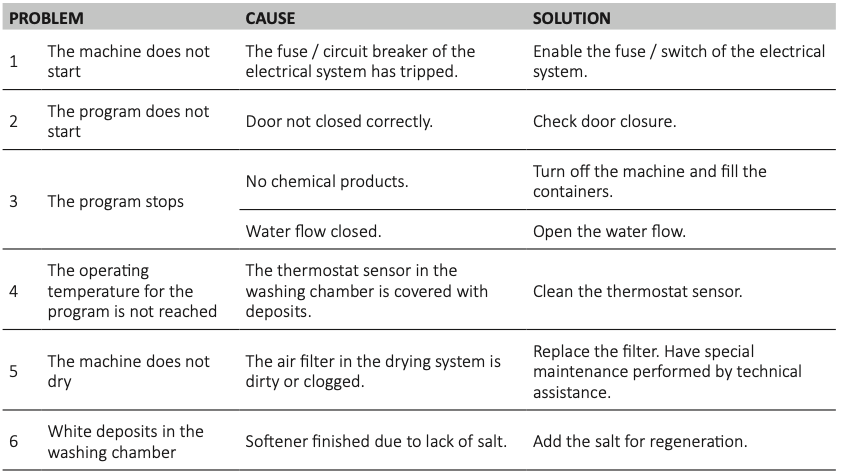

The annex 12.8 (shown below) lists the main malfunctions, with relative causes and recommended solutions, that the machine may present during its operation.

The interventions that may become necessary must be carried out by experienced and qualified operators.

If the problems persist or appear even more often after performing the work reported below, contact the technical assistance or an authorized and qualified service personnel.

Equipment Disposal

Equipment Disposal

Respect the laws in force in the country of use of the machine, in relation to the use and disposal of the products used for the cleaning and maintenance of the machine, as well as observe what the manufacturer of these products recommends.

When disposing of a washer disinfector, it is necessary to remember that it can still be contaminated by blood and other organic liquids, pathogenic germs, genetically modified material, toxic or carcinogenic substances, heavy metals, etc. and, therefore, it must be decontaminated before its disposal.

For safety and environmental protection reasons, dispose of all chemical residues in compliance with applicable legislation. When performing this operation, use protective goggles and gloves. Remove or disengage the door lock so that no one can get closed inside the machine, e.g. children playing. Finally, deliver the machine to a suitable and authorized collection centre. The electrical and electronic devices to be disposed of contain reusable materials.

They also contain components harmful for the environment, but necessary for the correct operation and safety of the equipment. If they are not disposed of correctly or are disposed of as household waste, these components can damage human health and the environment. Never dispose of the old washer disinfector among conventional waste.

Unauthorized product disposal by the user entails the application of very strict administrative sanctions provided for by current legislation. Enquire about this at your local dealer. Depending on the country in which one resides and the regulations in force, one is obliged to delete the data referring to people and stored on the machine.

Finally, make sure that the old equipment is kept out of reach of children until its actual disposal.

Spare Parts

The various components of the machine can be requested directly to the manufacturer by providing the following data:

Model, serial number and year of construction of the machine. These data are stamped on the identification plate fitted on each individual machine.

– Description of the part and required quantity.

– Shipping method. If this item is not specified, the manufacturer, although dedicating particular care to this service, is not liable for any shipping delays due to force majeure. Shipping costs are always charged to the recipient. Goods travel at the risk and danger of the customer, even if sold carriage free.

Finally, please note that the manufacturer is always available for any assistance and/or spare parts.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.