Tuttnauer 2540M Maintenance Guide

Recently, we wrote about the Tuttnauer 2540M, and created an installation guide and an operation guide for it as well, all available on our website. So this article will be continuing on to the next step, the maintenance guide. Here at SAS, we stress the importance of maintenance as often as we can, as maintaining your autoclave is one of the most important parts of ownership. The purpose of this article is to guide you through the maintenance of the 2540M, using the guide provided directly by Tuttnauer. It is important to follow these instructions carefully in order to ensure that any and all operation is carried out to the manufacturer’s specifications. If you would like to access a digital version of the 2540M manual, you can use this link to our resources tab where our manuals are located.

continuing on to the next step, the maintenance guide. Here at SAS, we stress the importance of maintenance as often as we can, as maintaining your autoclave is one of the most important parts of ownership. The purpose of this article is to guide you through the maintenance of the 2540M, using the guide provided directly by Tuttnauer. It is important to follow these instructions carefully in order to ensure that any and all operation is carried out to the manufacturer’s specifications. If you would like to access a digital version of the 2540M manual, you can use this link to our resources tab where our manuals are located.

We also have a Preventative Maintenance Checklist for the Tuttnauer 2540M here on our website.

Maintenance Guide

The maintenance operations described in this chapter need to be followed as indicated to keep the device in good working condition.

The instructions that follow can easily be carried out by the office personnel and do not require a service technician.

Daily

Clean door gasket with a mild detergent, water and a soft cloth or sponge. The gasket should be clean and smooth.

Weekly

1.) ONCE PER WEEK, clean the air jet. To ensure that the

temperature inside the chamber rises properly, it is necessary to keep the air jet clean. A dirty air jet will prevent indicator strips from changing color and cause spore tests to fail.

2) Once per week, clean and descale the chamber, copper tubes and the reservoir using Chamber Brite

Caution

Do not use steel wool, steel brush or bleach as this can damage the chamber and trays!

3.) Take out the tray holder and trays. Clean the tray holder and trays with detergent or a non-abrasive stainless steel cleaner and water, using a cloth or sponge. Rinse the tray holder and trays immediately with water to avoid staining the metal.

4.) Put a few drops of oil on the 2 door pins and door tightening bolt screw shaft and bearing.

5.) Clean the outer parts of the autoclave with a soft cloth.

Periodically

- Once every month, clean and check the safety valve.

- Replace the door gasket every 12 months, or as needed.

- Once a year, inspect the locking device for excessive wear.

Draining the Reservoir

Caution:

Before starting, ensure that the electric cord is disconnected and there is no pressure in the autoclave.

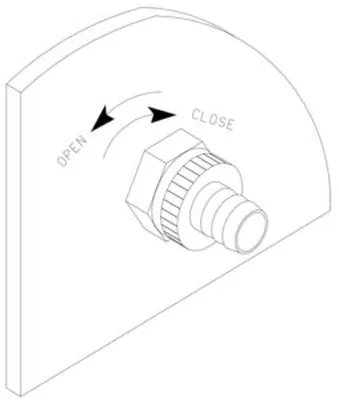

The drain valve is located on the front left side of the autoclave after the door is opened. The function of the drain valve is to drain the water reservoir.

- Connect the silicone hose, supplied with the autoclave, to drain into a bucket.

- Turn drain valve counter clockwise to the open position.

- Fully drain the reservoir

- With a quart of tap water flush out the reservoir

- Turn drain valve clockwise to the close position.

- Connect the electric cord to power source.

- Fill the reservoir with distilled water to just below the safety valve

- Turn on the main power switch.

- The autoclave is now ready for use.

Cleaning the Air Jet

(Located in the water reservoir.)

A dirty air jet is the number one cause of failed spore tests

The elimination of air from the sterilization chamber during heat up is critical to the proper operation of the autoclave. Failure of the air removal system will be responsible for incomplete sterilization, indicator strips that do not turn and failed spore tests.

The air jet consists of a small orifice with a clean out wire inserted in it (wire is permanently installed and will not come out). It is required that the air jet be cleaned once per week or more often if necessary, to remove any accumulated dirt and debris.

It is preferred to clean the air jet when the unit is running a cycle and under pressure. This is so that any loosened debris will be blown away, however, it can be done while the unit is idle.

- Remove the water reservoir cover.

- Clean the hole of the jet by manipulating the air trap wire back and forth 10 times

It is important to clean the hole of the air trap, as described at point 2 before starting operation of the autoclave, for the first time.

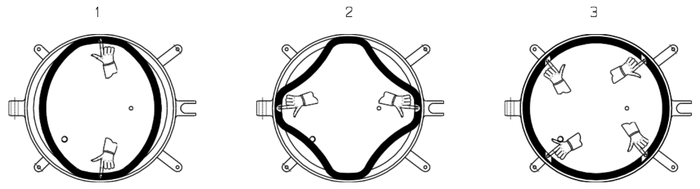

Replacing the Door Gasket

Pull off the gasket from the door groove. Install the new gasket as described in drawings 1, 2 and 3 below.

Caution!

Caution!

This gasket is designed with a trapezoidal cross section. The gasket should be placed with the widest side towards the door.

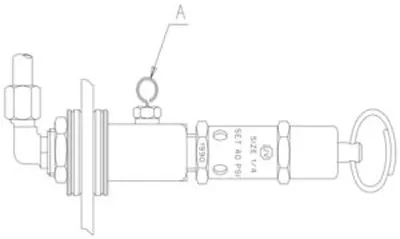

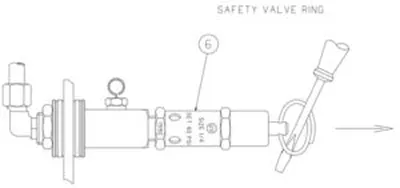

Checking the Safety Valve

(Located in the water reservoir)

In order to prevent the safety valve from becoming blocked, it is necessary to allow the steam pressure to escape through the valve. This procedure should be done every month as follows:

1. Run a sterilization cycle with a sterilization temperature of 273°F according to the manual.

2. Allow a pressure of approximately 29 psi (200 kpa) to build up in the chamber.

3. Turn the timer back to 0 minutes.

4. Remove water reservoir cover

![]() Caution!

Caution!

This next step will expose you to HOT STEAM

![]() Caution!

Caution!

To avoid being burned, by hot steam, do not place your face over the safety valve.

5. Pull the ring of the safety valve using a tool, i.e. screwdriver, hook etc. and open the safety valve for 2 seconds then release. Be careful not to burn your hands.

6. Verify that the valve releases steam and closes immediately.

7. If the safety valve is stuck in the “open” position, let the pressure decrease to zero (atmospheric pressure).

8. After the pressure in the chamber decreases to zero, pull the valve ring to release the valve.

9. Repeat operations 1 to 6.

10. If the valve is stuck again in the open position, call for service.

11. After a successful check, turn the multi-purpose valve to the Exh/Dry position.

12. Wait until the pressure decreases to zero, only then can the door be opened.

Unclogging the Multi-Purpose Valve or Fill Piping

- Pour distilled water into the chamber, according to quantities mentioned in para. 4 (Installation Instructions).

- Close the door.

- Turn the multi-purpose valve to STERILIZE position.

- Move the main switch to the ON position.

- Turn the Thermostat knob to 273oF (134oC).

- Turn the Timer knob to 20 minutes.

- After the timer has reached “0” turn the multi-purpose valve (clockwise) to the FILL WATER position, do not stop at any other position.

In most cases, the pressure pushes the obstructing substance out and the steam exhausts into the water reservoir. - When the pressure gauge reaches 0, turn the multi-purpose valve to the “0” position, and the main switch to OFF.

- Open the door.

- Replace the water in the water reservoir.

The autoclave is ready for the next cycle. - If this procedure does not clear up the clogging, a technician will be required to replace the multi-purpose valve or clear the piping.

VERY IMPORTANT!

When sterilizing cotton wool or pads, it is essential to wrap them in paper or cotton bags in order to prevent the multi-purpose valve and the autoclave openings from becoming clogged with remnants of the material.

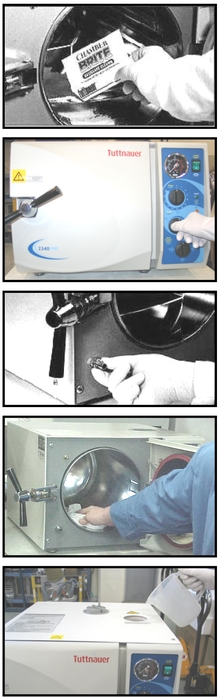

Cleaning the Tabletop Autoclaves with Chamber Brite

CHAMBER BRITE is a cleaning and descaling agent designed specifically for the cleaning and removal of water deposits, oxides and other sediments that are found in steam sterilizers. The material is a combination of acidic salts and additional cleaning materials.

Chamber Brite autoclave cleaner has been formulated specifically to be a fast, powerful and easy to use cleaner for steam sterilizers.”

If the autoclave is not cleaned regularly, dirt and debris will build up and clog the tubing and valves. This dirt can also be transmitted to the instruments during sterilization. In addition, a layer of dirt on the stainless steel chamber traps moisture against the metal and will lead to the chamber becoming porous and failing.”

“It is recommended that your autoclave be cleaned with CHAMBER BRITE once per week”

Caution! NEVER use bleach, steel wool, a steel brush or anything abrasive to scrub or clean the chamber.

Cleaning Procedure

- Important – all steps in this procedure must be completed without interruption.

- When the autoclave chamber is cold, remove instruments and trays from the autoclave.

- Open the door and spread the contents of a packet in a straight even line along the bottom of the chamber, from back to front.

- 4 Start a sterilization cycle* with water and No Drying Cycle according to the manufacturer’s instructions. When the cycle is finished, exhaust the unit.

- At the end of the exhaust cycle, drain the water from the reservoir.

- Fill the water reservoir with distilled water.

- Repeat a sterilization cycle without Chamber Brite powder, to remove any excessive dirt in the pipes. Start a sterilization cycle* with water and No Drying Cycle according to the manufacturer’s instructions. When the cycle is finished, exhaust the unit

- At the end of the exhaust cycle, drain the water from the reservoir.

- Turn the autoclave off and allow chamber to cool.

- Remove the tray holder; wipe the interior of the chamber with a damp cloth.

- Fill the reservoir with distilled water only.

- Wipe the tray holder with a damp cloth and return it to the chamber.

- Turn fill knob to fill position and allow a small amount of water (2-4 ounces) to fill chamber. Remove water from chamber.

- The autoclave is ready to use.

IMPORTANT!

DO NOT sterilize instruments during the cleaning process!!!

CAUTION!

Keep out of reach of children. Contains mildly acidic ingredients. Avoid contact with the skin, eyes or clothing. Wash hands well after touching the powder, in the case of eye contact flush with continuous running water for at least 15 minutes. If irritation persists get medical attention. If accidentally swallowed, do not induce vomiting, drink large amounts of water and obtain medical attention. MSDS available upon request.

For models 1730, 2340, 2540 use one packet of CHAMBER BRITE TM. For models 3140, 3850, 3870 use two packets of CHAMBER BRITE TM. Clean every 20 cycles or as needed.

* Total cycle time for cleaning Tuttnauer “M” series is 30 minutes at 273°F (134°C). Total cycle time for cleaning Tuttnauer “MK” series is 15 minutes at 273°F (134°C). All cycles referenced are from a cold start.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.