Maintenance on a Midmark M11 Self-Contained Steam Sterilizer Leave a comment

Maintenance on a Midmark M11 Self-Contained Steam Sterilizer General Instructions*

In this article, we want to share Midmark’s proper procedures for maintenance on their M11 Self-Contained Steam Sterilizer. We will cover Maintenance Messages, Daily Maintenance, Weekly Maintenance, Monthly Maintenance, and Extended Use Maintenance. And if you just want to talk to someone, call our Free Tech Support at 704-966-1650 Option 3.

Let’s start with Maintenance Messages

To assure proper operation and maximum sterilizer life, carefully follow all recommendations for periodic maintenance. Recommended maintenance is easy to do and takes very little time.

One of the MOST important steps you can take to prevent problems with your M11 sterilizer is to ensure that ONLY distilled water or water that meets the referenced water purity specifications – NOT TAP WATER – is used in the sterilizer. Since the sterilizer operates with high water temperatures, any minerals dissolved in the water will form mineral deposits. This can prevent valves from opening or closing properly and can also lead to corrosion in the chamber and tubing.

Maintenance reminders will be displayed on the screen at the appropriate intervals to assist the operator. These reminders are removed from the display screen once a cycle is started.

The user is responsible for establishing a periodic maintenance procedure to assure the correct operation of equipment and reliable sterilization of loads. Contact your local Midmark distributor or service representative to develop a program for planned maintenance.

Next is Daily Maintenance

Clean External Surfaces

A) Wash the exterior of the M11 sterilizer each day according to your facility’s procedure for clinical contact surfaces, noting the following: (Use only quaternary disinfectants to disinfect unit. Staining, pitting, discoloration, or softening could occur if phenolic, iodophor, or glutaraldehyde-based disinfectant is used on plastic surfaces of the unit. Also, the use of alcohol or aerosol spray cleaner/disinfectant containing substantial amounts of alcohol in the formula can damage the faceplate).

B) Wring excess solution from the cloth.

C) Using a soft cloth, wipe all external surfaces of the M11.

D) Follow the instructions provided with the cleaner/disinfectant used regarding the rinsing and drying of the external surfaces.

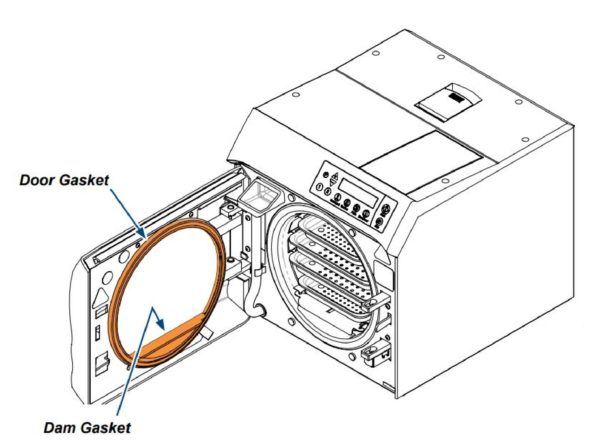

Clean Sterilizer Door / Dam Gaskets

A) Examine gaskets for possible damage.

B) Clean gaskets and mating surfaces with a damp cloth.

Now for Weekly Maintenance

Clean chamber/Trays (including Rack and Plate)

A) Disconnect the upper portion of the reservoir drain tube from the panel clips, bend it downward, and drain the reservoir water into a suitable container, e.g. a bucket, and dispose of the water.

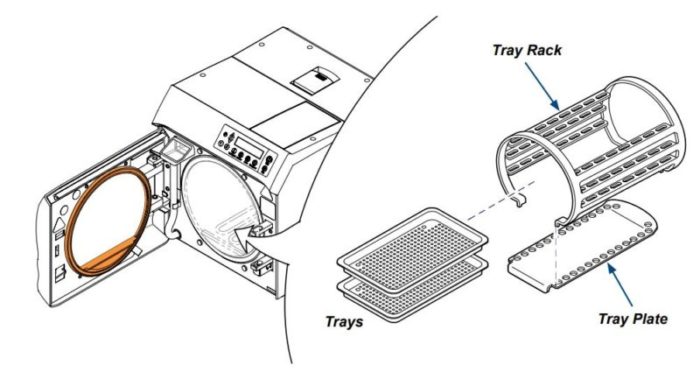

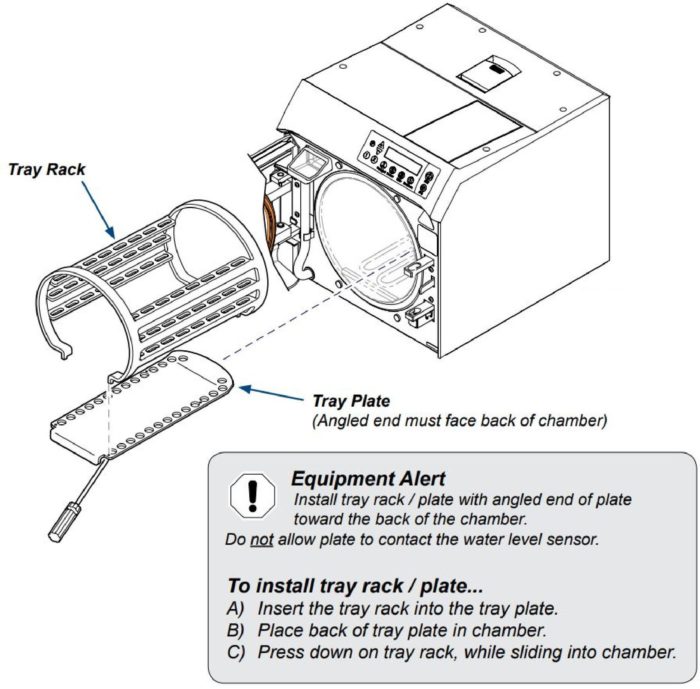

B) Remove the trays, tray rack, and tray plate from the sterilizer.

C) Wash trays, rack, plate, and inside of the chamber with mild soap or Speed-Clean and distilled water or water that meets the referenced water purity specifications.

D) Refill reservoir with distilled water or water that meets the referenced water purity specifications.

Monthly Maintenance

Clean Chamber and Plumbing

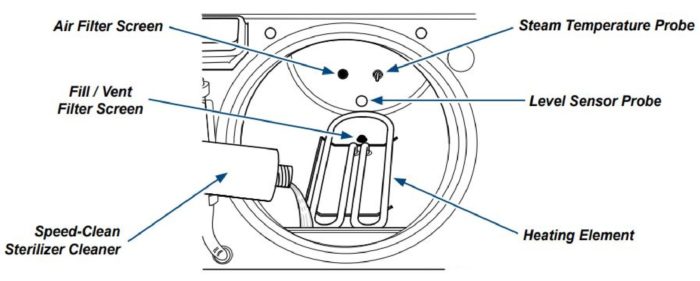

H) Remove and clean filters. The M11 filters are intended to prevent debris from causing valve failures. Between regular monthly cleanings if the fill or vent times become too long or items will not dry the filters should be cleaned. (Refer to the illustration for the location of filter screens.)

I) Grasp filter and gently pull away from the chamber wall while twisting slightly. (If necessary, pliers may be used to remove filters)

J) Clean filters with Speed-Clean and distilled water. A small stiff-bristled brush or ultrasonic cleaner may be helpful. Rinse filters with distilled water. Replace filter(s) if debris cannot be removed by cleaning.

K) Wipe out the inside of the M11’s chamber.

L) Install filters. (Press inward, toward chamber wall while twisting slightly).

M) Install tray plate, rack, and trays.

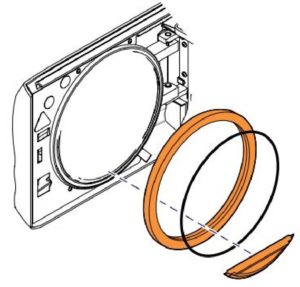

Remove/Clean Door and Dam Gaskets

A) Remove door and dam gaskets from chamber door, then remove the gasket ring from the door gasket.

A) Remove door and dam gaskets from chamber door, then remove the gasket ring from the door gasket.

B) Clean gaskets and ring with Speed-Clean, distilled water, and a soft brush.

C) Inspect gaskets for damage / shrinking / swelling. Replace gaskets if damage is apparent.

D) Press gasket ring into the channel in the door gasket and reinstall the gasket in the door.

E) Install dam gasket.

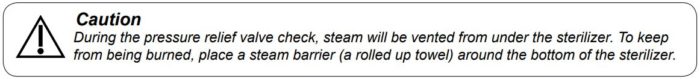

Check Pressure Relief Valve

(must be checked each month to assure it functions properly)

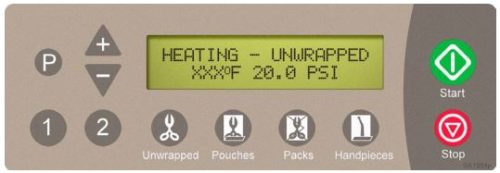

A) Press the ![]() Unwrapped button

Unwrapped button

B) Press the  Start Button

Start Button

C) Wait until the pressure in the chamber reaches 20 PSI (138 kPa).

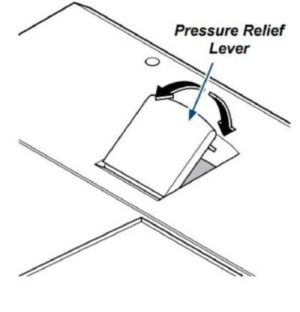

D) Pull upward firmly on the pressure relief lever for approximately 3 seconds, then release.

(Steam should discharge freely from beneath the rear of the M11 when the lever is pulled. If the valve does not close completely when the lever is released, pull the lever again and release quickly so that it snaps closed. Repeat this until the valve seats properly).

E) Press the  Stop Button (This aborts the cycle to prevent overheating).

Stop Button (This aborts the cycle to prevent overheating).

![]()

Equipment Alert If excessive force is required to open the pressure relief valve, or if the valve will not reseat properly, the valve must be replaced.

Lastly is Extended Use Maintenance

The M9 / M9D and M11 are designed and tested to provide exceptional reliability throughout their service life. However, like all electro-mechanical devices, they are subject to wear and degradation with use.

To ensure the integrity, performance, and safety of all major components it is the responsibility of the user to have the sterilizer performance/operation verified by a Midmark Authorized Service Provider at least every 10 years or 10,000 cycles, whichever comes first. After 10 years or 10,000 cycles of use, an annual inspection by a Midmark Authorized Service Provider is recommended.

Preventive Maintenance Trials and Tribulations

Preventive Maintenance is ABSOLUTELY Needed to keep your equipment running properly and reduce downtime. But do all the different maintenance time frames and processes seem impossible to keep up with? Are you tired of trying to keep track of which sterilizer needs what done and when?

Well, we are here to remove all the burden and let you focus on your work. We offer a FREE PREVENTIVE MAINTENANCE PROGRAM to remove all the headaches and worries that come with this necessity.

It doesn’t matter if you have 1 Midmark sterilizer or 5 of them. It doesn’t even matter if you have 10 (or more) sterilizers and autoclaves of different makes, models, and sizes. We will keep track of ALL your units and let you know when it is time for any and all preventive maintenance to be performed on each machine.

Let us help you take the worry out of such an important task. It is truly an ABSOLUTELY FREE SERVICE! Just sign up and we will take care of the rest.

We also offer FREE TECH SUPPORT (even if you didn’t buy from us) so if you’re having any trouble with any of the steps in this article just give us a call and we can get you through it.

And don’t forget our FREE TECH VIDEOS on our YouTube channel that cover a multitude of processes, parts, cycle faults, and much more information about sterilizer and autoclaves.

If you have any questions at all please feel free to contact us and we will gladly help.

*All information taken from Midmark M9/M9D/M11 Self-Contained Steam Sterilizer User Guide TP202 20-42-FO-00014 Rev A1 C2189

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.