Introduction to the SciCan Bravo G4

In this article, we’re going to use the official guide to help you in introducing your new SciCan Bravo G4 unit! This introduction guide is exact to the resources provided. But if you have any further questions or prefer to speak to a technician live, call our Free Tech Support at 704-966-1650 Option 3.

General Characteristics

The device is an electronic steam sterilizer, entirely operated by a micro-processor, with a large, moulded stainless steel sterilization chamber.

It is characterized by an advanced fractionated vacuum system for the complete removal of air, even from hollow, porous materials, and an effective final vacuum drying phase capable of eliminating all traces of humidity from any load.

The exclusive steam generation system, the effective hydraulic circuit and the electronic management (integrated by high-precision sensors) ensures high execution speed of process and an excellent stability of thermodynamic parameters.

Moreover, its Process Evaluation System constantly monitors all the machine’s “vital” parameters in real-time, guaranteeing absolute safety and a perfect result.

The device offers users 6 sterilization programs (one of which completely programmable), all equipped with customizable, optimized drying for the effective sterilization of the various types of load (instruments and materials) used in a medical environment.

All the cycles can be selected on the clear LCD screen, which also allows extensive configuration of the device according to the user’s needs.

Like in the best tradition, the new range of autoclaves feature the most complete and advanced safety systems available today, to ensure the user against any operation, electrical, mechanical, thermal or functional fault.

Technical Specifications

Summary Table

Device BRAVO G4 17 BRAVO G4 22

Manufactured for SciCan Ltd. A Coltene Group Company

1440 Don Mills Rd., Toronto, ON, Canada, M3B 3P9Same as 17

Input voltage 240 V~ 60 Hz 120 V~ 60 Hz Same as 17

Main fuses

(6.3 x 32 mm) (0.25 x 1.26 in)2x T15A 250V Same as 17

Electronic board fuses

(5 x 20 mm) (0.20 x 0.79 in)F1: T3.15A 250V (transformer primary 240 V~ 60 Hz / 120 V~ 60 Hz) Same as 17

Nominal power 2300 W (for 240 V~)

1440 W (for 120 V~)Same as 17

Insulation class Class I Same as 17

Installation category Cat. II Same as 17

Environmental operating conditions

Indoor use

Temperature: +15°C (+59° F) ÷ +35°C (+95° F)

Relative humidity: between 20% and 80% max. non-condensing Height: min -100 m ( - 328 ft) / max 3000 m (9842 ft) (above sea lev.) Pollution degree max: 2Same as 17

A-weighted sound power level (ISO 3746) < 67 db (A) Same as 17

External dimensions (HxWxD) (rear connections excluded) 456 x 480 x 600 mm 17.95 x 18.90 x 23.62 in Same as 17

Net weight: unladen approx. 49.60 kg / 109.34 approx. 51.30 kg / 113.09

Net weight: unladen, with tray holder support and trays approx. 51 kg / 112.44 lbs approx. 53 kg / 116.84

Net weight: unladen,

with tray holder support, trays and water at MAX. levelapprox. 56.50 kg / 124.56 approx. 58.50 kg / 128.97

Sterilization chamber dimensions

(D x D)250 x 350 mm 9.84 x 13.78 in 250 x 450 mm 9.84 x 17.72 in

Sterilization chamber total volume approx. 17 L (0.017 cu. m) approx. 22 L (0.022 cu. m)

Sterilization chamber usable volume (with tray holder support inserted) approx. 10 L (0.010 cu. m) approx. 13 L (0.013 cu. m)

Sterilization chamber usable dimensions 17 L (1.38x1.55x2.97) dm / 6.4 cu. dm 22 L (1.38x1.55x3.97) dm / 8.5 cu. dm

Water tank capacity (filling) approx. 5.5 L (water at MAX. level)

approx. 1 L (water at MIN. level)Same as 17

Sterilization programs 5 standard programs + 1 program defined by the user Same as 17

Device BRAVO G4 17 BRAVO G4 22

Test programs B&D Test Vacuum Test

Vacuum Test + B&D TestSame as 17

Pre-heating time(from cold) approx. 10 min. Same as 17

USB connection Key capacity lower than or equal to 2GB: FAT formatting with 16K/ sector

Keys capacity higher than 2GB:

FAT32 formatting with 16K/sectorSame as 17

Printer connection * Serial RS232 (printer cable max. length 2.5 m – 8.20 ft) Same as 17

240 V 60 Hz Main power cord Plug NEMA 6-15P 250V-15A

SJT 14 AWG / 3C 300V 60° C (140° F)

Connector C19 acc. to IEC 60320Same as 17

120 V 60 Hz Main power cord Plug NEMA 5-15 125 V-15A

Cable SJT 14 AWG / 3C STYLE 1015 60° C (140° F)

Connector C19 acc. to IEC 60320Same as 17

Ethernet connection RJ45 (max. cable length 29 m – 95.14 ft) Same as 17

WiFi 802.11 b/g/n (2.4 Ghz); WEP / WPA / WPA2-PSK encryption Same as 17

Bacteriological filter (filter element in PTFE) Porosity: 0.027 microns

Connection: male connector 1/8” NPTSame as 17

Maximum flow of drained water 1 L/min. Same as 17

Temperature of drained water 50° C / 122° F Same as 17

Max. temperature of drained water 90° C / 194° F Same as 17

Total heat in Joule sent by the sterilizer to the surrounding air in 1 hour of continue operation 17 L = 3.6 MJ 22 L = 4 MJ

Maneuver/handling space 1mx1m 3.28 x 3.28 ft Same as 17

Device BRAVO G4 17 BRAVO G4 22

Working pressure -0.8 ÷ 2.4 bar -0.8 ÷ 2.4 bar

Safety device setting 2.4 bar 2.4 bar

* The optional external printers Ref. M7D200012 is compatible with the BRAVO G4.

Safety Devices

The sterilizer is equipped with the following safety devices for which we provide a brief description of their function:

Mains fuses (see data in summary table)

Protection of the whole device against possible failures of heating elements. Action: power supply interruption.

Electronic circuit protection fuses (see data in summary table)

Protection against possible failures of the primary circuit of the transformer and of low voltage users. Action: interruption of one or more low voltage circuits.

Thermal circuit-breakers on mains voltage windings

Protection against possible overheating of pump motors and of transformer primary winding. Action: temporary cut-off (until cooling) of the winding.

Safety valve

Protection against overpressure in the sterilization chamber. Action: release of the steam and restoration of the safety pressure.

Safety thermostat with steam generator manual reset

Protection against steam generator overheating. Action: cut-off of the electricity to the steam generator.

Safety thermostat with chamber heating element manual reset

Protection against overheating of the heating elements of the container under pressure. Action: cut-off of the electricity to the chamber heating element.

Door position safety microswitch

Confirmation of the correct closing position of the door of the container under pressure. Action: signaling of wrong door position.

Motor-driven door lock mechanism with electromechanical protection (pressure switch)

Protection against accidental opening of the door (even in a blackout). Action: prevents accidental opening of the door during a program.

Door locking mechanism safety microswitch

Striker for the correct closing position of door locking system.

Action: signaling of failed or wrong operation of door locking mechanism.

Self-leveling hydraulic system

Plumbing system structure for the spontaneous leveling of the pressure in the case of a manual interruption of the cycle, alarm or blackout.

Action: automatic restoration of atmospheric pressure in the sterilization chamber.

Integrated system for evaluating the sterilization process

Continuous verification of the sterilization process parameters entirely managed by microprocessor. Action: immediate interruption of the program (in case of malfunction) and generation of alarms.

Sterilizer operation monitoring

Real-time oversight of all significant parameters when the machine is powered.

Action: generation of alarm messages (in the case of anomaly) with possible interruption of the cycle.

Water Supply Characteristics

Only use demineralized / distilled water having the following characteristics to supply the sterilizer.

Description Values in the Water Supply Values Inside Residual

Dry Condensate < 10 mg/L < 1 mg/L

Silicone Oxide SiO2 < 1 mg/L < 0.1 mg/L

Iron < 0.2 mg/L < 0.1 mg/L

Cadmium < 0.005 mg/L < 0.005 mg/L

Lead < 0.05 mg/L < 0.05 mg/L

Heavy Metal Residues (Iron, Cadmium and Lead Excluded) < 0.1 mg/L < 0.1 mg/L

Chlorides < 2 mg/L < 0.1 mg/L

Phosphates < 0.5 mg/L < 0.1 mg/L

Conductivity At 20° C / 68° F < 15 μS/cm < 3 μS/cm

pH Value 5 -7 5 -7

Aspect colorless, transparent, without sediment colorless, transparent, without sediment

Hardness < 0.02 mmol/L < 0.02 mmol/L

When buying demineralized / distilled water, make always sure that the quality and characteristics declared by the manufacturer are compatible with those specified in the table.

![]()

The use of water for steam generation with presence of contaminants with levels exceeding those indicated in the above table can greatly shorten sterilizer lifetime.

This could also result in an increase of oxidation in the most sensitive materials as well as in an increase of limescale residues on generator, boiler, internal supports, trays and instruments.

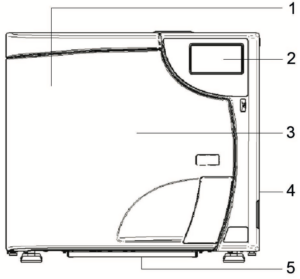

Front

- Model

- Control panel and LCD screen

- Door

- Power switch

- Anti-dust filter

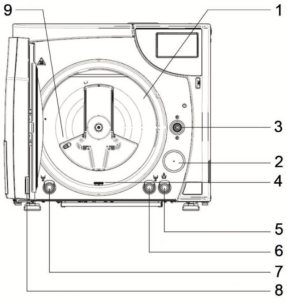

Inside

- Sterilization chamber

- Bacteriological filter

- Door locking system

- Water drainage filter

- Front filling quick connector

- Clean water reservoir drainage quick connector

- Waste water drainage quick connector

- Door

- Steam diffuser

Rear

- Fastening slots for rear spacers

- Heat exchanger

- Connection for direct water drainage

- Connection for automatic demineralized / distilled water filling (only for H2O AUX EV kit (AUX SV) and automatic filling accessory kit)

- Data plate

SERIAL NUMBER LABEL (See image *) - Ethernet cable connection (max. length 29 m / 95,1444 ft)

- Serial cable connection

- Automatic filling electrical connection (only for H2O AUX EV kit (AUX SV) and automatic filling accessory kit)

- Network fuses

- Power cable connection

LCD Icons

The screens in the following pictures may vary in shapes and colors, but their contents are the same as shown on the sterilizer display.

- Selection for data management & connectivity

- Selection of sterilization and test cycles

- Time and date

- Button for quick download of new cycles

- System info selection

- Door unlock

- Selection of the sterilizer settings (Setup)

![]()

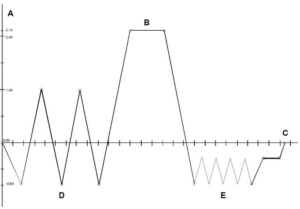

Example of Working Cycle

The sterilization program can be effectively described as a succession of phases, each one with a very precise objective.

For example, a B CYCLE program: after loading the material in the chamber, closing the door, selecting the program and starting the cycle (after locking the door opening mechanism), the following sequence will occur (see the graph below):

- Steam generator and sterilization chamber pre-heating.

- Air removal and steam penetration in the material through a series of vacuum (extraction of air and fluid

from the sterilization chamber) and pressure (injection of steam into the chamber) phases. - Pressure rises with the consequent increase in the temperature of the steam, until reaching the conditions required for sterilization (in the example, 132° C / 269.6° F).

- Pressure and temperature stabilization.

- Load sterilization for the required time (in the example, 4 minutes).

- Sterilization chamber depressurization.

- Vacuum drying phase.

- Load ventilation, by means of sterile air.

- Pressure leveling, bringing the sterilization chamber back to the atmospheric pressure level.

Having reached this last phase, you can unlock the door and remove the load from the sterilization chamber.

It should be emphasized that phases 1, 3, 4, 6 and 9 are identical in all cycles, with slight variations of duration that are solely dependent on the quantity and consistency of the load and the heating conditions of the sterilizer while phases 2, 5, 7 and 8 clearly vary their configuration and/or duration on the basis of the cycle selected (and, as a consequence, the type of load) and the choices made by the user.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

The SciCan Bravo G4 17L unit is available for purchase here.

The SciCan Bravo G4 21L unit is available for purchase here.