The Dangers of Autoclaves

While we can admit that the autoclave is probably not the flashiest, or most exciting machine on your counter, it is one that gets a great deal of use, is critical to your business, and is often handled by a good number of staff each day. These machines are built for high-pressurization cycles, giving them the ability to clean tools under 10 minutes. That intense pressurization, when handled improperly, can cause damage to the instruments inside, the facility surrounding the unit, and people handling the machine.

Autoclave safety is what we advocate for the most when it comes to these machines. Existing cases and the prevention of future cases is the reason we have so many ways to share the message with you. We have videos about preventative maintenance and how to perform it, blogs showcasing the parts with links to them for easy access, and regular emails about preventative maintenance. We even have our Free Preventative Maintenance Program, where you just give us your autoclave’s information and we keep you on track with maintenance. That is how dedicated we are to providing as high a standard in autoclave safety as we do. Our number one goal at SAS is to prevent you or anyone you work with from suffering a preventable injury that could possibly lead to something far worse.

That’s what today’s article is going to focus on. The dangerous implications of the exploding autoclave and how to ensure you are keeping your business and employees safe.

What Makes Them So Dangerous?

So at first glance, this answer may be a given. But it’s always important to go over the facts and make sure you know specifically why. This knowledge then prevents you from learning the facts you don’t know the hard way.

Pressurization

Autoclaves are sterilization machines that are meant to sterilize under pressure. Some use steam, gravity, pre/post vac, etc. But they all have something in common. An airtight chamber and a very secure door locking mechanism. This is because, during sterilization, the steam is pumped into the chamber to replace the normal air. After that, the exhaust valve on the autoclave is closed. This leaves only the pressurized steam in a hot, airtight, sealed chamber. The temperature and pressure rise to the desired sterilization settings, and that’s how the magic happens.

Because of how the history of the autoclave came about, the easiest way to describe them is comparing them to their predecessor, the pressure cooker. Eventually after a while they realized that the idea of a pressurized steam chamber could not only cook food, but sterilize things too. Thus, we eventually got the autoclave. But if you think back to your school science class, there’s a reason that the chamber is airtight. See, if the seal keeping the air in had a hole or anything of that nature, the air would slowly leak out. With the pressure dropping in tow. But what happens when all of that steaming hot pressure is released all at once? Like say, if the door wasn’t completely secure when the cycle started, and instantly buckled under the pressure of the chamber?

The Damage

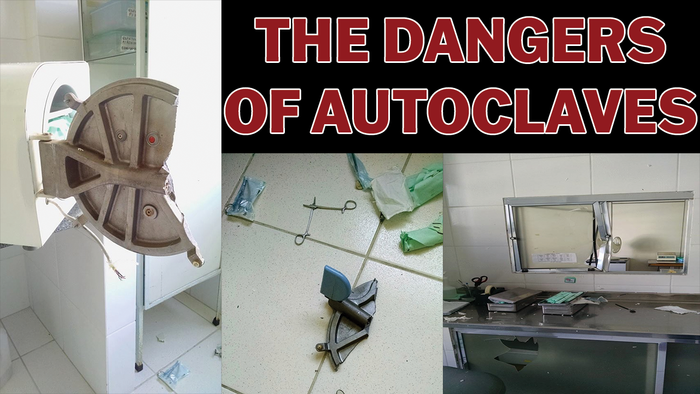

How about this autoclave explosion from a dental office in Porto Alegre, Brazil? This was uploaded to a dental blog site, netdentista. The article this story is from, loosely translated, said that no one was in the office when this explosion happened. But it goes on to say that if someone was there, it would’ve been very serious. And they’re absolutely right. No one got hurt in this instance, but what if someone did?

The Unfortunate Cases

So that last case we mentioned, when that door chunked and came off, no one was around thankfully. But, just as there are cases where there weren’t any injuries or casualties, there’s always the other side of that coin. So, to show you just how important this topic of safety is, we’d like to review a couple of cases. Cases where people have found themselves on the receiving end of the explosion, that show the dangers of autoclaves. Cases that have resulted in severe damage and even death by autoclave explosion.

Case #1: Elaine Davidson

Now, this case isn’t as expanded as some of the others we’ve found. It’s very cut and dry, but still an example of why learning how to properly take care of your autoclave is important. On November 7th, 2013, an article was written by the Stokes and Kopsky personal injury law firm. This article was about a case involving one 57-year old Elaine Davidson, that took place about a week prior, on October 31st. Elaine was one of the unfortunate cases to be caught in the explosion of a preventable autoclave explosion. On that day, the autoclave she was using at work had exploded. Forcing the door off of the machine in the blast, sending it into the path of Davidson, who suffered severe injuries. She later succumbed to these injuries when she was later admitted to the hospital after the explosion.

Now, this case is very sad. No one should lose their life to negligence. Davidson had a 37-year career ended at the hands of a preventable accident. As later on, records showed that the autoclave that exploded had problems with the door nearly 2 and 4 years apart prior to this case. From that same article, “Maintenance records obtained by a local news channel dating from 2008 and 2010 indicate that there had been ongoing problems with the autoclave door.”

Not much else was said about this case, just the cause of the explosion and the unfortunate aftermath. But cases like these do exist even if you don’t hear about them often enough to believe it. Learning how to properly handle your autoclave and maintain it lets you gain a better understanding of the dangers of the autoclave. If you’re not convinced, then let’s show you our other example.

Case #2: Michael Whinfrey

January 11, 2011, a 42-year old Michael Whinfrey and his colleague were the unlucky recipients of a stainless steel door blown off the autoclave. The British Safety Council says that Whinfrey suffered fatal head injuries and that his colleague was “fighting for his life.” These injuries coming from a blast that “blew a hole into the factory wall.” But, here’s the kicker, the door to the autoclave had “been a problem for quite some time.”

And when the investigation into what triggered the explosion was concluded, the evidence proved many ridiculous things about the way the company operates. But also it proved that, the explosion, and subsequently the deaths, were preventable. The Justice on this case said, of the company: “Mike Whinfrey died as a result of systemic failings in the way the running of this autoclave was managed and operated by you. A substantial element in those failings was attributable to your senior management.” And as it turns out, he was exactly right.

The investigation led them to test out the two autoclaves this company had. And this test showed that a screw that secured the door to the machine was loose. The autoclaves had built up wear and the door rings tore consistently and even moved during sterilization. All of this, from the fact that the court found that the company purposely neglected important functions to cut corners and save money. Like, modifying the autoclaves by REMOVING THE SAFETY DEVICES.

Britain’s Health and Safety Executive (HSE) at the time, Carol Downes said this of the company: ” (They) didn’t properly understand the risks of, and lacked the competence in, operating steam pressure autoclave systems.” Things like this are why we advocate so heavily for proper safety and training of autoclave handling. These kinds of things can be prevented.

What Can You Do?

Thankfully, there’s a very easy answer to this. Keep in mind these cases can’t be ignored. They’re examples as to the dangers of autoclaves and why they can’t afford to be taken lightly. Learning how an autoclave works is one thing. Learning how to make sure it works properly is another story. It’s not just close the door and press a button then wait. You need to make sure you’re doing everything properly as you were (hopefully) trained to do. No slacking, and do not neglect your training.

Make sure that what goes in the autoclave is what’s supposed to be there. Make sure the seal is in good condition. Ensure the door is tight and secured. Make sure everything is in proper order before starting the cycle. Check for maintenance issues. Do your scheduled maintenance to ensure any parts wearing down get replaced with all new ones. These steps can and will keep you and employees in your workplace safe.

Final Thoughts

Safety is something we at SAS advocate for more than anything. This is important, autoclaves can be dangerous in untrained hands. You cannot afford to neglect the needs of your autoclave. Every part you replace, every cleaning you do, every step you take to ensure that your autoclave is in working order, is one step you take to keeping everyone safe in the office.

Luckily, the steps you have to take are easy enough to remember. Ensure that your autoclave door is closed completely before use. Keep up with your daily, weekly, monthly, quarterly and yearly maintenance. And make sure no corners are being cut to avoid safety. And if you think you don’t know what to do, we’ve got you covered. We have a YouTube library full of maintenance tutorials, overviews and more. Or if you’d like to contact us, you can do so at the links below. We’re always here to help, especially if it means the safety of you and your colleagues.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.