SciCan HYDRIM C61W G4 Maintenance Guide

We’ve recently talked about the SciCan HYDRIM C61W G4 Instrument Washer, and showed you how to install it, operate it, and store its data. And now we’re going to continue our guide through its processes with the Hydrim C61W G4 Maintenance Guide. These instructions come from the manufacturers themselves. For proper practices when maintaining your Hydrim C61W G4 when needed. And if you have any questions about this or anything else, you can call us at 704-966-1650, option 3 for our free tech support.

guide through its processes with the Hydrim C61W G4 Maintenance Guide. These instructions come from the manufacturers themselves. For proper practices when maintaining your Hydrim C61W G4 when needed. And if you have any questions about this or anything else, you can call us at 704-966-1650, option 3 for our free tech support.

Maintenance

Replacing the HIP Ultra Cleaning Solution

Only replace the cleaning solution with HIP Ultra cleaning solution, which is used in dilute form as a detergent for the cleaning of surgical instruments in the HYDRIM washer.

It is a non-hazardous, non-flammable, non-toxic, colorless and almost odorless liquid that is completely soluble in water. Nonetheless, some precautions must be taken to safely handle this chemical. For more information, see the Hydrim C61W G4 Installation Guide, section: Handling and Installing the HIP Ultra cleaning solution.

NOTE: To avoid spillage, replace the solution container only when the message appears and be sure to wear gloves.

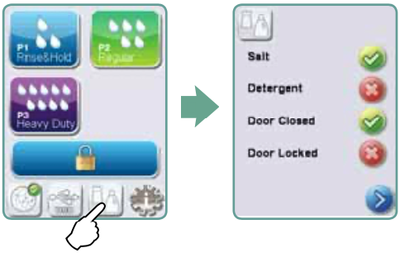

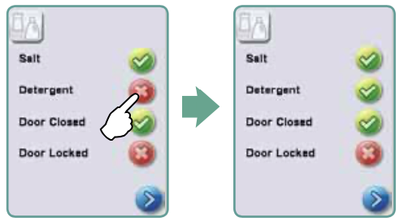

When a red X appears on the water softener/detergent icon. Press on the icon to determine if the problem is with the water softener or cleaning solution level. If the cleaning solution must be replaced, a red X will appear next to it.

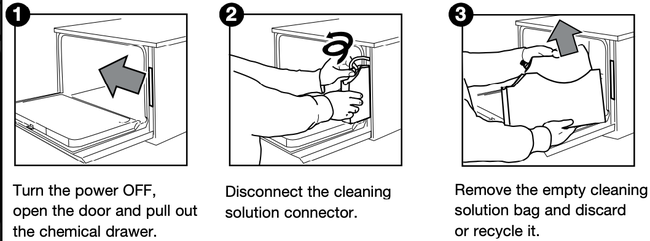

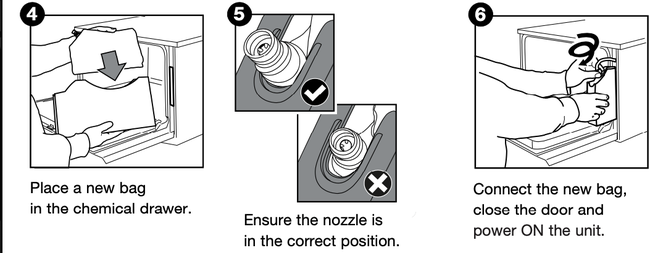

To replace the cleaning solution, follow these steps:

To replace the cleaning solution, follow these steps:

To prime the cleaning solution dosing pump, press the water softener/detergent icon on the main screen. In the water softener/detergent screen, press the red X next to “Detergent”. The unit will prime the dosing system and a green check mark will appear in place of the red X when it is ready for use.

NOTE: The system can also be primed by simply starting a cycle and selecting “Detergent Replaced”, when prompted.

NOTE: The system can also be primed by simply starting a cycle and selecting “Detergent Replaced”, when prompted.

Refilling the Water Softening Water Reservoir

When a red X appears on the detergent and water softener level indicator, press on

the icon to determine if the problem lies with the water softener or cleaning solution level. If the water softener must be refilled, follow these steps:

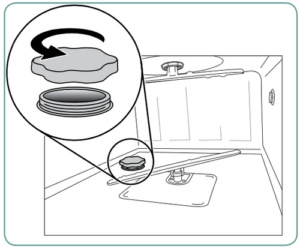

- Open the salt container lid.

- Fill the salt container to the top, using the funnel supplied, to a maximum of 0.5 kg.

- Close the salt container lid, ensuring a tight seal. An improper seal can lead to corrosion.

- Run a complete cycle, with no instruments.

Changing the Air Filter

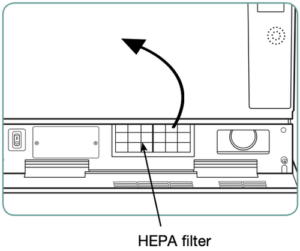

When the message “Replace air filter” appears, the HEPA filter is in need of changing. Turn the power off. Pull open the ventilation panel below the front door of the unit. Make note of the direction of the arrow and remove the old filter by pulling it from the centre. Install the new air filter – placing the arrow in the correct orientation – and close the ventilation panel.

After replacing the filter, go to the “Reset Drying Counter” screen in the Setup menu and reset the drying counter to zero.

The filter must be replaced every 750 drying cycles. The unit will continue to run if the filter is not replaced, but you will notice less than optimal drying performance.

Filter and Wash Arm Maintenance

Filter Maintenance

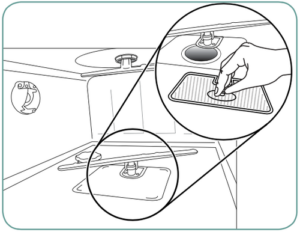

Inspect the coarse and fine filters in the bottom of the chamber daily for debris and clean if necessary. To clean, remove the filter (turn the metal nut at the centre front of the filter to release it), rinse under a tap and reassemble. Ensure that the filter is firmly locked into position when replaced.

Wash Arm Maintenance

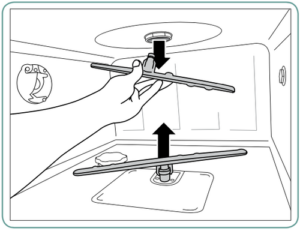

If you see that the wash arms are not turning easily, remove the arm(s) as needed – excessive removal of wash arms can reduce service life. Both the upper and lower arms are pressure mounted.

To remove the upper arm, pull down and to remove the lower arm, pull up. Rinse under a tap, clear obstructions from outlet holes and reassemble.

Cleaning the Unit

To clean outer surfaces and the decal covering the touchscreen, use a soft cloth moistened with soap and water or a surface disinfectant. Do not use harsh cleaning chemicals.

To clean the chamber, use the “Cleaning” function available in the user menu with 0.5 L of vinegar in the chamber. See section 4.8 for details.

NOTE: Every 25 cycles, the user will be reminded to run a chamber cleaning cycle. Press OK to continue the selected wash cycle but remember to run a chamber cleaning cycle at the next available opportunity.

Preparing the Unit for Shipping

If preparing the unit for transport or storage, waste water should be removed from the sump. Waste water in the unit may contain biological contaminants. From the Setup menu, select the Prepare for Shipping function. The unit will pump all the waste water from the sump. If a small amount remains, soak it up with absorbent material. Wear disposable rubber gloves. Dispose of absorbent material according to biological waste disposal regulations.

If the unit is without power, use the drain tube located under the front of the unit in the middle to drain the water from the chamber and system. Then unlock the door using the door lever and remove the coarse filter and fine filter and use absorbent material to soak up any water remaining in the sump.

Annual Maintenance

If the message “Preventative Maintenance Required. Call for Service” appears, the annual maintenance is required. To continue using the HYDRIM, press OK. Call for service as soon as possible. The annual maintenance should be done after 365 days have elapsed since the initial installation or since the last service call was performed.

Unit Testing and Validation

The following outlines the recommended regular maintenance to be performed by the user and technicians for the HYDRIM C61w G4 washer.

To ensure the unit’s ongoing cleaning efficacy, SciCan recommends observing the following periodic testing protocols.

The recommended periodic testing protocols are listed in the table below:

When Who What Tests

Upon installation By a SciCan-approved technician Commissioning/Installation testing as outlined in the installation document included with the unit.

Daily tests and checks By the user • door lock check

• wash arm rotation check

• door seal check

• load carrier check

• check and clean chamber filters

• visual examination (inspection under

magnification) of each load for residual soil.

Annually By a SciCan-approved technician Annual maintenance schedule as outlined in the service manual

IMPORTANT NOTES:

This document outlines the minimum requirements to ensure that the equipment performs to specification. In some regions, local/national guidance documents may require additional testing. Please contact your dealer or local medical authorities for details.

Installation, commissioning, annual servicing MUST be undertaken by SciCan approved technicians. Failure to maintain this equipment may invalidate the results of the following testing regime.

Tests to be performed by the user:

Door lock check

This test is to ensure that the door cannot be opened while a cycle is running or a cycle will not start with the door open. To check that these features are working correctly, attempt to open the door using the handle immediately after a cycle has started. Caution – DO NOT attempt this when the wash arms are rotating and/or the water is above ambient temperature. The door should not open. When you attempt to start a cycle with the door open, the cycle should not start. If the unit fails this test, stop using it immediately and call your dealer for technical service.

Door seal check

Visually check the door seal for debris or wear. If the seal is worn or damaged, call your dealer for technical service.

Load carrier check

Visually check load carriers (trolleys) for wear and tear, damage and that the runners move freely over their full range.

Chamber filter check

Remove, visually check and clean as described in section 6.4.

Load check

Visually inspect each load for residual soil. Washers are designed to ensure that the surfaces of instruments are free from debris that may compromise the sterilization process. A visual check of the instruments processed in each load should be undertaken prior to sterilization to ensure that no residual debris is present on the instrument.

If debris is still apparent, the instrument should not be considered clean and should be reprocessed through the HYDRIM again prior to sterilization.

NOTE: Some set-able materials such as cements and composites, if set on the instrument will not be removed in a HYDRIM. If these materials are noticed on the instrument then abrasive removal may be required.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

The SciCan Hydrim C61W G4 Instrument Washer is available on our site here.