Tiva 8-L Software and Printer Guide

This article is a continuation from our Tiva 8-L Operation Guide. In this article, we’re going to go over how to properly manage the USB devices, software and printer for the Tiva 8-L. The way Tuttnauer recommends.

Software Desktop

General Information

On request, the glass-washer comes with a desktop software, called “WasherRePortal”, that gives enhanced features to the User. With this software, in fact, it’s possible to:

- create and print digital versions of the reports;

- connect the device to the PC to customize the user names and passwords via USB port (cable not included; use USB 2.0 only, system does not support USB 3.0);

- save the information coming from multiple devices;

- import and export the database of reports;

- export comma separated value files (*.CSV) for post-processing activities (free files editable with third-part softwares like MS Excel).

IMPORTANT NOTE! The software comes with a free one week (7 days) trial period, at the end of the trial period you must contact your dealer or distributor to enter the activation code to continue using the software.

If you have the software, please refer to the user manual for more information regarding the use.

Bluetooth

The glass-washers are equipped with bluetooth card that allows, through the use of the “RePortal” app, to download a .DTA file or export a PDF file on your device (equipped with bluetooth technology), containing all the information about the cycles performed by the glass-washer.

The .DTA file can be opened with the “Washer RePortal” software to view all the informations and export the repots to your computer.

IMPORTANT NOTE! It is not possible to have USB and bluetooth technology together. If Bluetooth is present, USB is not available.

Plugs

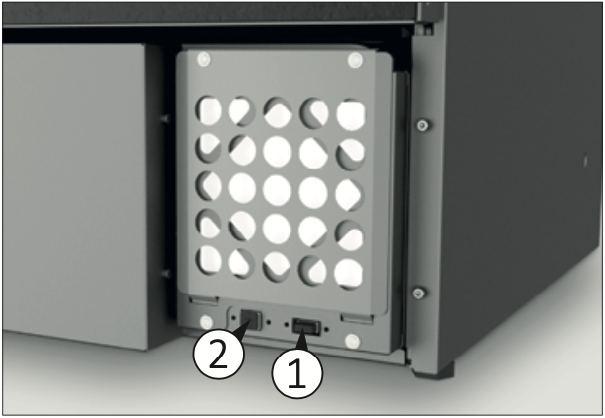

USB Plugs

Two different types of USB are present:

1) USB type A for pen-drive: see chapter “USB Key Management”.

2) USB type B is used to connect an external PC.

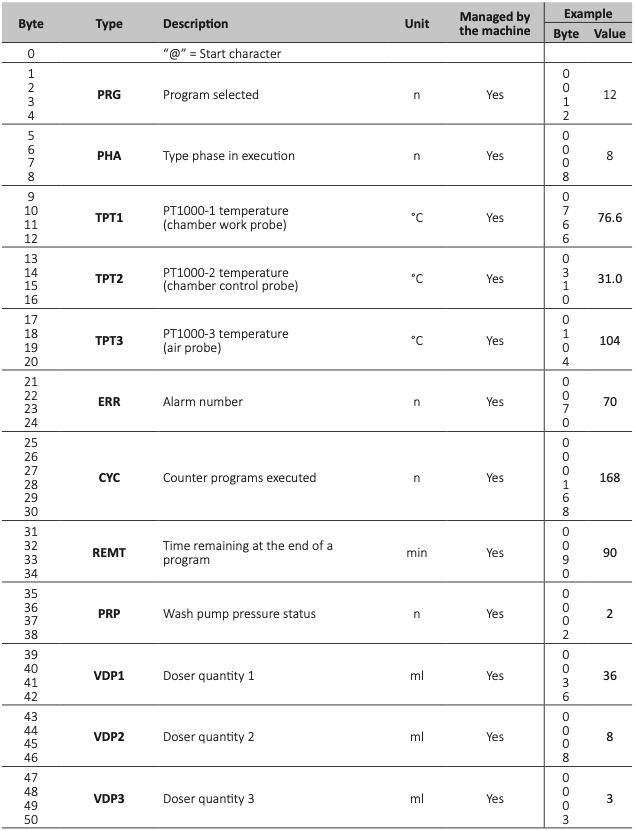

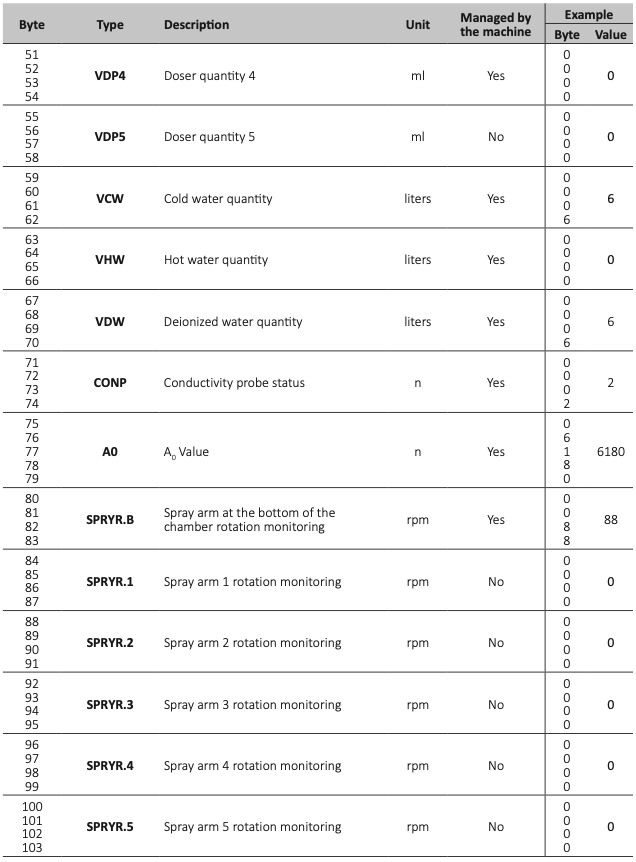

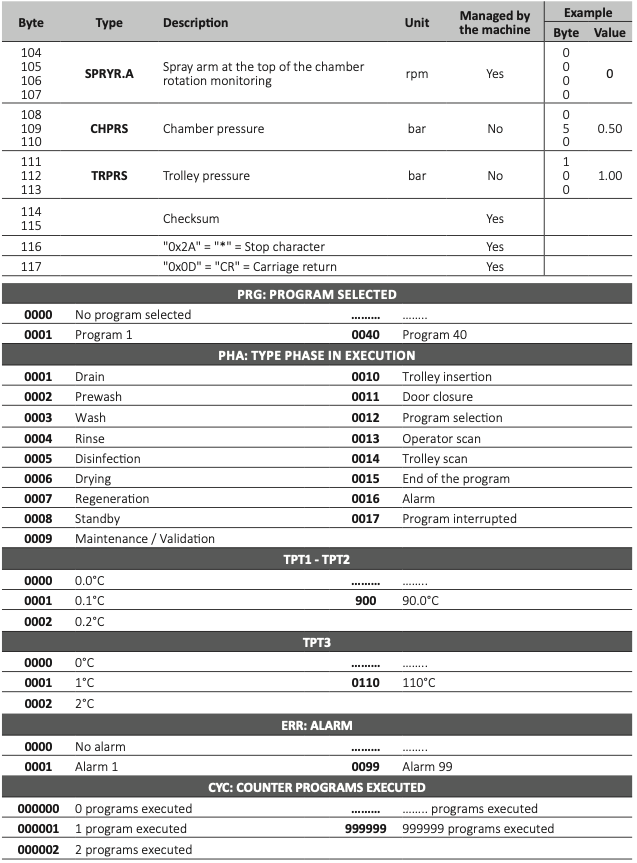

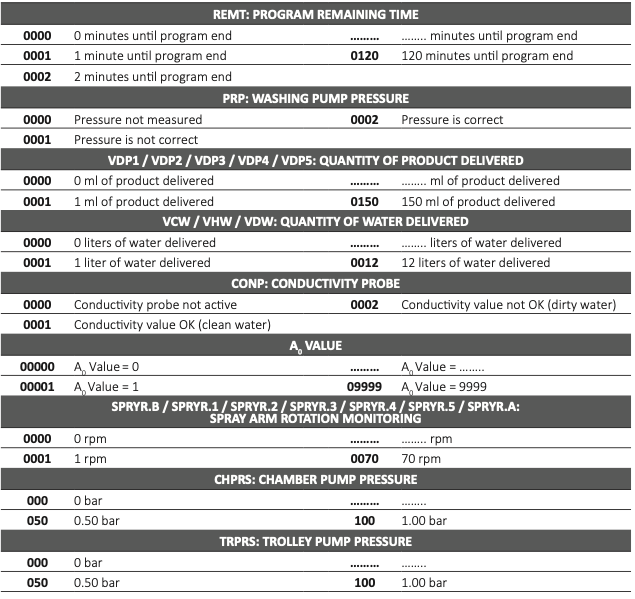

The following data are transmitted every second from the micro board (RS232 connector) to the modem that will manage them. These data are sent constantly (even if the device is in stand-by mode).

Serial protocol:

- Baudrate: 19200. – Data bits: 8.

- Parity: None.

- Stop bits: 1.

- Flow control: None.

PRG – Selected program: The code of a program stay active until that program is finished. When the program is over, the code goes back to 0000. If an alarm is triggered and the machine is set to go back to standby mode after the alarm has been reset, the code goes back to 0000.

PRG – Selected program: The code of a program stay active until that program is finished. When the program is over, the code goes back to 0000. If an alarm is triggered and the machine is set to go back to standby mode after the alarm has been reset, the code goes back to 0000. - PHA – Current phase: The code of the phase the machine is performing is updated every time a phase change occurs.

- TPT1, TPT2: The PT1000 1 probe is the work probe of the chamber, the PT1000 2 probe is the control probe of the chamber. The value increases by 0.1°C at a time.

- TPT3: The PT1000 3 probe is the probe for air heater. The value increases by 1°C at a time.

- ERR- Alarms: 0000 means that the machine is not in an alarm state. When an alarm is triggered, its code will be transmitted until the alarm is reset.

- CYC – Programs executed counter: This is the counter of the programs the machine has performed.

- REMT – Program remaining time: Time remaining (in minutes) to cycle completion. When an alarm is triggered, this code is reset after the alarm is reset. When the device is in stand by, the code 0000 is transmitted.

- PRP – Washing pump pressure: Transmits the status of the wash pump.

- VDP1, VDP2, VDP3, VDP4, VDP5 – Quantity of product delivered: This code is reset every time a phase of the program ends.

- VCW, VHW, VDW – Quantity of water delivered: This code is reset every time a phase of the program ends.

- CONP – Conductivity probe: Transmits the status of the conductivity probe.

- A0 Value: The A0 code can go up to 99999 and is maintained until the program ends (like the A0 value on the display). If an error occurs, the A0 value is reset after resetting the alarm. If a program has more than one disinfection phases, this code is reset whenever a disinfection phase starts.

- SPRYR.B, SPRYR.1, SPRYR.2, SPRYR.3, SPRYR.4, SPRYR.5, SPRYR.A – Spray arm rotation monitoring: The value of rotations per minute of the spray arm is transmitted. If an alarm is triggered this value is reset after alarm reset.

- CHPRS: In the case of a machine equipped with a pressure transducer on the chamber pump, this value is transmitted.

- TRPRS: In the case of a machine equipped with a pressure transducer on the trolley pump, this value is transmitted.

Loading the Printer Paper Roll

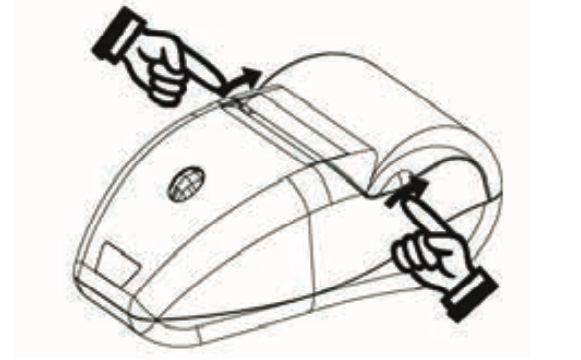

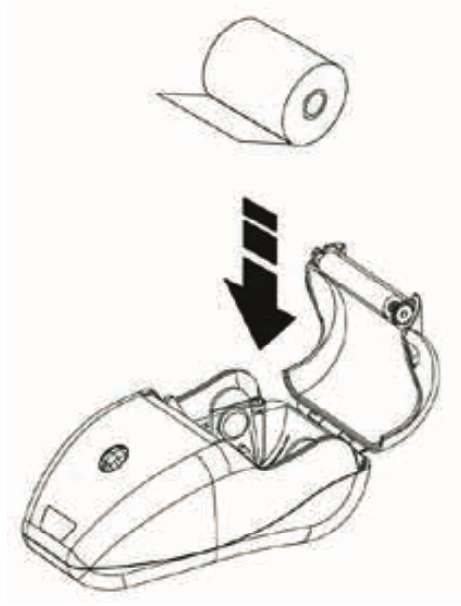

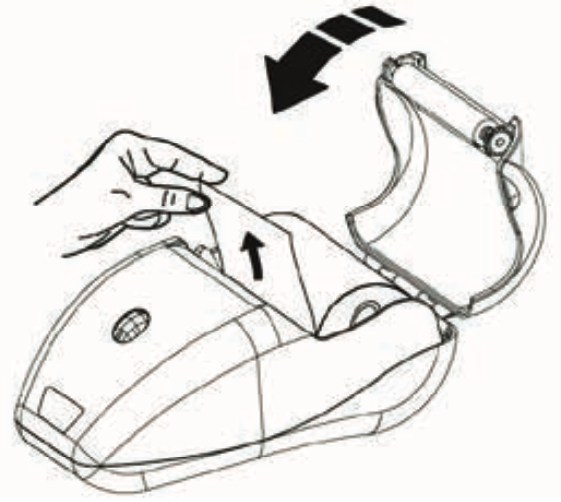

To change the paper roll, proceed as follows:

1) Open the printer cover lever in on the cover lateral projections.

2) Position the paper roll so that it unrolls in the direction shown.

3) Pull upon the edge of the paper and close the cover.

4) Remove the excess paper. Switch-off and switch-on the machine. The printer is now ready.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.