Tuttnauer 2540M Installation Guide

Recently, we wrote about the Tuttnauer 2540M, one of the many manual autoclaves we have in stock on our website. In this article, we will provide an in-depth explanation of the installation process for the Tuttnauer 2540M, which is a manual tabletop autoclave designed for multi-doctor practices, clinics, and surgery centers. The purpose of this article is to guide you through the installation of the 2540M, using the installation guide provided directly by Tuttnauer. It is important to follow these instructions carefully in order to ensure that the installation is done correctly according to the manufacturer’s specifications. If you would like to access a digital version of the 2540M manual, you can use this link to our resources tab where our manuals are located.

Installation Guide

Caution:

![]() The sterilizer must be placed on a rigid and leveled surface. The stand must be able to hold the load of the device and loaded material.

The sterilizer must be placed on a rigid and leveled surface. The stand must be able to hold the load of the device and loaded material.

Note:

Make sure, when placing the autoclave, to leave space around the machine, to give the technician access to service the machine.

Electrical

The electrical connection should comply with the devices power requirement. It must also comply with local installation and safety rules and regulations. The voltage supplied to the device must comply with the label ± 5%.

In order to avoid any injury by electrical hazard, it is mandatory for the customer to have installed an earth leakage relay (GFI outlet or circuit breaker) in the electrical circuit to which the autoclave is connected. This relay disconnects all the poles of the electrical power line in case of accidental contact by the power line, with the autoclave’s metal enclosure.

Note: Keep the back and the right side of the autoclave approximately 1” (25mm) away from the wall to allow for ventilation.

Connect the power cord to the socket on the rear side of the autoclave; plug it into the supply outlet.

Setup

Proper adjustment of the chamber pitch is one of the most important things you can do for the sterilizer. Proper chamber pitch insures that among other things, the sterilizer will have the proper amount of water in the chamber at the beginning of each cycle. Insufficient water in the chamber, at the beginning of the cycle, will cause the unit to overheat and activate one of the safety thermostats. This will occur at some point during the cycle when the water level becomes too low. If, on the other hand, there is too much water in the chamber, this will extend the heating portion of the cycle. Extending the heat up time will shorten the sterilization time, causing items to not be sterilized, indicator strips to not change color and spore tests to fail.

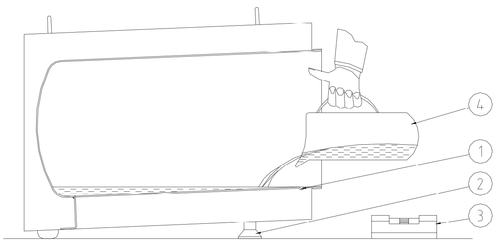

For proper setup please follow these setup steps (see drawing below):

- The autoclave should be turned off and unplugged.

- Make sure the counter is level and sturdy (3).

- Make sure all the feet are on the autoclave and none have been lost.

- Make sure the feet are free to move in and out (2).

- Position the autoclave on the counter.

- Fill the reservoir with distilled water.

- The chamber should be empty of any instruments, trays or leftover water.

- The chamber pitch now needs to be adjusted.

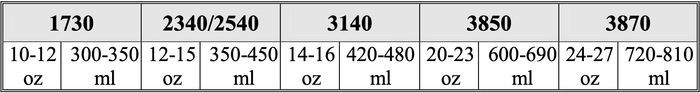

- Measure to the proper amount of distilled water for the appropriate model unit as listed below.

- Pour the proper amount of water into the chamber through the front door of the unit (4).

- This water should cover the bottom of the chamber to within +/- 1⁄2 inch of the groove in the front (1).

- If necessary, adjust the front leveling feet, up or down, so that the water lays in the chamber correctly (2).

- Once the chamber pitch adjustment is completed, the unit is ready to operate.

Note: It is imperative to have the correct amount of water in the chamber each cycle for proper operation of the autoclave.

Lifting and Carrying

Caution: Before moving the autoclave, make sure that the electric cord is disconnected from the power and there is no pressure in the chamber.

Disconnect the power supply cord.

Drain the water from the reservoir and vessel.

To avoid injuries, lifting and carrying should be done by two people. Do not drop this device!

Water Quality

The distilled or mineral free water supplied to the autoclave should have the physical characteristics and maximum acceptable level of contaminants indicated in the table below:

Physical Characteristics and Maximum acceptable contaminants levels in steam for sterilizers.

(According to EN 13060:2004).

Element Condensate – allowable content

Silicium oxide. SiO2 ≤0.1 mg/kg

Iron ≤0.1 mg/kg

Cadmium ≤0.005 mg/kg

Lead ≤0.05 mg/kg

Rest of metals except iron, cadmium, lead ≤0.1 mg/kg

Chloride (Cl) ≤0.1 mg/kg

Phosphate (P2O5) ≤0.1 mg/kg

Conductivity (at 20°C) ≤3 μs/cm

pH value (degree of acidity) 5 to 7

Appearance Colorless clean without sediment

Hardness (Σ Ions of alkaline earth) ≤0.02 mmol/l

Compliance with the above data should be tested in accordance with acknowledged analytical

methods, by an authorized laboratory.

Attention: We recommend testing the water quality once a month. The use of water for autoclaves that does not comply with the table above may have severe impact on the working life of the sterilizer and can invalidate the manufacturer’s warranty.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.