What Are Some Common Mistakes When Using Sterilization Pouches?

Your autoclave is powerful. A work of masterful machinery containing the evolution of centuries worth of sterilization technology. It’s able to take on the toughest and busiest work days to ensure that your instruments are sterilized to standard. But all of that power and capability comes at a cost. To ensure proper sterilization, you need to make sure that you do everything by the book, properly. From unboxing and operation to maintenance every step is vitally important. However, that also includes the factors outside of the autoclave itself, which is what we’ll be talking about today.

Tuttnauer, one of the biggest names in the industry, recently took a deep-dive into some of the most common mistakes one can make when it comes to handling sterilization pouches. Which is an important topic, since they’re essential to the sterilization process as a whole. So in this article, we’d like to look at some of these common mistakes when it comes to sterilization pouches. We’ll look at the various ways that other people have learned the hard way that there was an issue with how they handled their sterilization pouches. And with this guide, you can ensure that you can learn from their mistakes and not your own.

Incorrect Packaging Material

One of the first mistakes one can make is using the wrong kind of packaging altogether. Sterilization pouches exist for a reason, and there’s also a reason why you’ve never seen anyone sterilize their tools in a ziplock bag. Sterilization pouches are specially made to be penetrable by sterilizing agents, but also able to maintain sterility once the cycle is complete. Last time we checked, sandwich bags cannot withstand 250°F and intense pressure.

Always use sterilization pouches for your instruments, there’s many options available to you. These sterilization pouches are created to help reach and maintain the industry standards. As well as offer variety with unique features to help keep your tools sterile.

Overfilling Your Pouches

This one should seem like a simple fix, don’t overpack your sterilization pouches. Overfilling your sterilization pouches can lead to issues like blockages that prevent proper steam penetration and overall sterilization. Overfilling sterilization pouches can result in the outer layers being sterilized while everything else inside is still contaminated.

Ensure that everything in the pouch is packed to standard, and that they have ample room for sterilization. If you find yourself running out of room, use another sterilization pouch to divide and conquer. One extra pouch is worth it if it saves you from a potential headache or improperly sterilized tools.

Improperly Wrapped Pouches

This is an important one. Properly wrapping your sterilization pouches can help to prevent a compromised load. On the pouches themselves, there’s usually some kind of indicator to let you know where to properly seal it. Whether it’s a perforated edge or a dotted line, you should always follow the indicator.

If the seal is too tight, and you went beyond the line, the plastic layers will make contact during sterilization and prevent proper sterilization. So, be sure to wrap the pouches according to the indicator, leave it secure and loose to allow proper steam penetration. And if you use self-sealing packages, the dotted line should always be used to prevent excess folding.

Using Damaged Packages

If you have a tear, puncture, hole, or any other kind of break in the seal, your sterilization pouch’s barrier is entirely compromised. Any breach allows microbes from the outside to make their way in, and this pouch is unusable for sterilizing anything.

Be sure to carefully inspect all of your pouches before use. And when you’re dealing with sharp instruments like scalpels and the like, use caution. Be sure to pack them carefully and correctly to avoid any accidental punctures in the pouch. If an instrument is found protruding from the cassette or tray, it needs to be repackaged immediately. And if any damage is found on the sterilization pouch itself, the pouch must be discarded, and all the instruments inside need to be reprocessed inside of a new, un-punctured pouch.

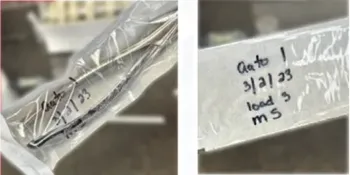

Improper Labeling of a Package

Accurate record-keeping is vital to infection control and risk management. Sterilization pouches are labeled with key pieces of information to ensure that when it’s stored. This label are made so it can be easily read and handled accordingly based on when it was sterilized. This step is done so it can be validated before use.

Missing any essential information prevents traceability, which we’ve talked about before. If a spore test is performed on an autoclave and comes out positive for bacteria, knowing that key info is important, so you know which loads need to be reprocessed. Each pouch should clearly be marked with:

- Date

- Load number

- The sterilizer it was sterilized in.

- And the name of whoever prepped it.

This labeling system allows for a swift identification process, and subsequent quarantine and recall if a test fails.

The Use (or Lack) of Chemical Indicators

Relying on the autoclave’s display screen or other visible metrics alone is insufficient. You need clear, visible proof that the sterilization parameters were met inside of the pouch. That’s why chemical indicators are used inside of the pouches. Chemical indicators are essential visual tools. Failing to use an external indicator means that you can’t quickly verify that a package has been processed. Also, failing to use an internal indicator means you cannot confirm if the steam and heat had adequately penetrated to the instruments.

Always use a temperature-sensitive indicator on the outside of the pouch (for a visual cue that the package has been processed). It’s also crucial to place a comprehensive chemical indicator (integrator) inside the pouch that responds to multiple variables like time, temperature, and pressure. This internal indicator offers the ultimate assurance that all sterilization variables were met.

Single-Use Means Single-Use

Sterilization packaging materials that are marked for single-use are designed for one purpose and cycle only. Reusing them is a dangerous shortcut you should never take. Sterilization wraps and pouches are not designed for repeated exposure to high heat and steam. Reusing them can cause the materials to break down, weakening the sterile barrier. As well as significantly increasing the risk of contamination.

Never reuse sterilization pouches or wraps. Adhering to the single-use rule for all sterilization packaging materials is a foundational step in reducing cross-contamination. This is foundational information for maintaining a robust infection control program in your clinic.

Final Thoughts

Your autoclave is the central powerhouse of your infection control ecosystem. A highly engineered machine designed to meet the highest safety standards. But as you’ve read, that power is conditional, and it only goes so far on its own. The integrity of your sterilization process doesn’t end when you hit the ‘start’ button; it actually begins the moment you package your instruments.

Common errors like using damaged material, overfilling, or forgetting a comprehensive chemical indicator are not minor mistakes; they are immediate failures of the sterile barrier. By moving past the hard lessons learned by others and embracing these tips for proper sterilization packaging… you ensure that every instrument leaves the autoclave truly sterile. Also that they remain that way until the point of use. This attention to detail is the non-negotiable step that protects both your staff and patients from any potentially dangerous problems that you can run into when you work with contaminated tools.

If you have any questions about sterilization pouches and their use, or any other instrument sterilization issues, please give us a call at 704-966-1650 and we’ll help you find what you need.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.