Midmark M9 and Midmark M11 Preventative Maintenance: Daily, Weekly, and Monthly Tasks Leave a comment

StatimUSA.com has a FREE PREVENTATIVE MAINT PROGRAM – CLICK HERE TO SIGN UP!!

In the mid-19th century, French chemist Louis Pasteur found that bacteria can be killed at 120 degrees Fahrenheit. He invented the sterilization technique of boiling or heating instruments to kill microorganisms and his efforts eventually led to the use of the autoclave as a standard medical tool. While our Statim autoclave systems are effective for numerous sterilization applications, keeping them properly maintained is essential to consistent performance. Here’s a quick guide to help you understand the ideal daily, weekly, and monthly cleaning tasks for your Midmark M9 or Midmark M11 sterilizer. And if you just want to talk to someone, call our Free Tech Support at 704-966-1650 Option 3.

Daily Maintenance

First, it should be noted that anybody performing these maintenance tasks should allow the unit to cool completely in order to prevent burns and injuries. Start your daily autoclave maintenance by washing its exterior according to the procedures set by your facility. You should use only quaternary disinfectants, and as always, consult the owner’s manual for more specific information. In addition to cleaning, you should also examine the door gaskets (M9 Gasket – M11 Gasket) for any damage and clean them with a damp cloth as well.

Weekly Maintenance

Weekly maintenance tasks focuses primarily on cleaning the inside of the system. Start by draining the water from the reservoir if necessary. Remove the inside components such as trays, racks, and plates (M9 Tray Kit – M11 Tray Kit), and wash them thoroughly and the inside chamber using mild soap or Speed Clean and water. Finally, refill the reservoir will clean water that meets the purity standards set my the manufacturer.

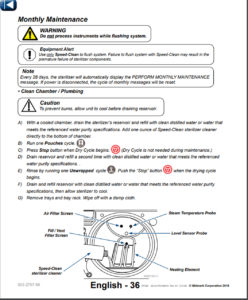

Monthly Maintenance

Finally, monthly maintenance involves flushing out the entire sterilizations system. After ensuring that the chamber is completely cooled, drain the reservoir and fill it with clean water. Then, add an ounce of Speed Clean to the bottom of the chamber and run the ‘Pouches’ cycle. Press stop after the Dry Cycle starts, then drain the reservoir and refill once again with clean water.

The reasons for autoclave failure typically fall into two categories: failure of the operator (human error) or mechanical failure due to age or improper maintenance. Taking proper care of your sterilization systems can prevent the need for Midmark autoclave repair services and maximize its lifespan. For more information about autoclave service companies, contact Statim USA.

StatimUSA.com is your number 1 resource for all things autoclaves, we sell new autoclaves, repair your old autoclave and even purchase your old autoclave back from you. Try us today, you wont regret it! You can reach us at info@statimusa.com or call our FREE TECHNICAL SUPPORT LINE at 704-966-1650.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

To see the full manual, click on the link below…