Tuttnauer 3870eap Autoclave Basic Overview & Manual Leave a comment

Thank you for visiting our site! Here’s the latest info from Sterilizer Autoclave Solutions. We hope you find this useful. Please know you can always call our office if you have any questions. And if you just want to talk to someone, call our Free Tech Support at 704-966-1650 Option 3.

Hey guys, Jason here from Sterilizer Autoclave Solutions in Charlotte, North Carolina. Today I want to do a high overview of the Tuttnauer 3870 EAP automatic autoclave that comes equipped with a printer. You’re probably asking yourself “Why would you want one of these?” Simply put… IT’S A POWERHOUSE!

As far as productivity goes, you have a 15″ X 30″ chamber here. You can sterilizer UP TO 14 POUNDS of equipment. It also comes with a 10-YEAR Chamber Warranty and a 2-year Manufacturer’s Parts and Labor Warranty on a brand new one. It comes with the stand here that has three shelf storage and multiple configurations. It also comes with three preset sterilization cycles and the ability to handle a Custom Cycle.

Sterilizer Autoclave Solutions sells this brand new, we do repairs on them, we service them, and stock all of the parts for them. Sterilizer Autoclave Solutions has FREE TECHNICAL SUPPORT for your Tuttnauer 3870 EAP. If you have any questions about the sale of one… WE WILL BEAT ANY COMPETITORS PRICE! Give us a call and let’s have a chat about your Tuttnauer 3870 EAP or talk about getting you into a new one.

See the New Tuttnauer 3870eap here: https://statimusa.com/product-category/tuttnauer/tuttnauer-new-autoclaves/3870ea-new/

If you need Tuttnauer 3870ea parts we have them here: https://statimusa.com/product-category/tuttnauer/tuttnauer-parts-rpi/3870ea-parts/

And remember we have FREE TECHNICAL SUPPORT – Even if you didn’t purchase from us we want to help you. Just call 704-966-1650… Press Prompt 3.

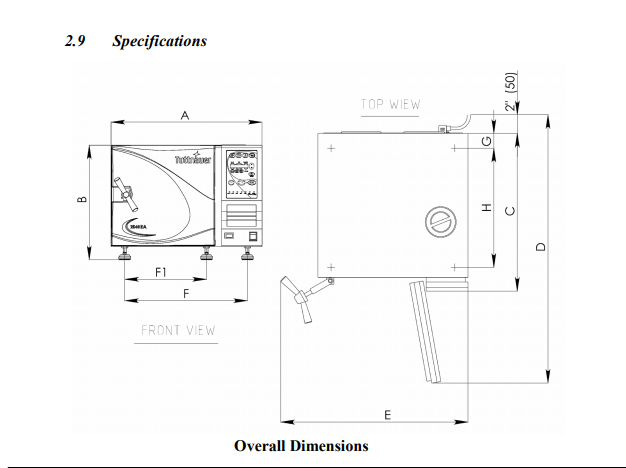

Operation and Maintenance Manual (pg 6-9)

Technical Data

2.1 Introduction

This tabletop autoclave is designed as a gravity displacement system for the sterilization of wrapped and unwrapped instruments and related items found in dental, medical and veterinary clinics, first aid rooms, hospitals, laboratories, etc.

This autoclave is an electrically heated sterilizer using steam as the sterilizing agent. A computerized control unit ensuring a fully automatic sterilization cycle, control and monitoring of physical parameters and a clear documentation of the sterilization cycle controls the autoclave.

The autoclave has three automatic programs, according to the material to be sterilized, and one auxiliary drying program. Models EA and EKA are equipped with an air compressor that, during the drying stage, draws air through a HEPA filter (0.2µm). It pushes that air through the heated chamber to remove moisture and facilitate the drying operation. Drying is performed with the door closed.

On all models (except 1730), a water pump is installed between the water reservoir and the chamber. This pump guarantees fast and accurate filling of the chamber every time. Entry of water may be accompanied by a noise for approximately 30 seconds. This is normal noise generated by regular operation of the pump.

The control system provides adequate protection to ensure the safety of personnel and reliable operation with a minimum of shutdown time.

On all models (except 1730), a printer is an optional addition to the autoclave. The printer prints the preset and actual parameters of the cycle (temperature, time and pressure).

This manual is intended for the user and gives the user a general understanding of the instrument and the best ways to operate and take care of it in order to obtain optimum effective results.

After reading this manual, operating the autoclave will be easy. However, since this instrument is built with high technology sensitive components, no attempt should be made by the user or any other unauthorized person to repair or recalibrate it.

Only technical personnel, having proper qualifications and holding technical documentation (including a technician manual) and adequate information are authorized to service the apparatus.

2.2 Standby Heating Mode

The autoclave provides an option of heating the chamber in standby mode between cycles with a very low power in order to reduce total cycle time (1.6% of the total power only). The autoclave turns off automatically if the interval between the sterilization cycles is more than 2 hours. This feature is standard on all EK, EKA models and optional on all E, EA models.

2.3 Environmental Emission Information

- The peak sound level generated by the autoclave is less than 70 dBA with background noise of 60 dBA.

- The total heat per hour transmitted by the autoclave is < 100 Wh for all models.

2.4 Operating Conditions

This device is to be used for indoor use. This autoclave is intended for NORMAL environment conditions as follows:

-

- Altitude up to 2000m.

- Room temperature range 41ºF to 104ºF (5ºC to 40ºC).

- Installation Category II. ¨ Pollution Degree 2.

- Maximum relative humidity 80% for temperature up to 31ºC decreasing linearly to 50% relative humidity at 40ºC.

- Main supply voltage fluctuations up to +/-5% of the nominal voltage.

The sterilizer should be loaded only with autoclavable material.

Caution!

Waste water should be brought into the public net in accordance with the local rules or requirements, i.e. ONLY NON-HAZARDOUS LIQUIDS SHALL BE DISPOSED IN PUBLIC SEWAGE!

2.5 Utilities

| Utilities | Unit | Value |

| Power supply (as appropriate) | V-A | 1 ph, 120V – 16A,50/60 Hz |

| V-A | 1 ph, 230V – 16A,50/60 Hz |

Attention:

The electrical net must be protected with a current leakage safety relay. The electrical network must comply with local rules or regulations.

2.6 Construction

The main parts of the autoclave are made of materials as indicated below:

-

- Chamber is electro-polish and built of stainless steel 316 L.

- Door is made of stainless steel CF8. ¨ Trays are made of stainless steel 316.

- Water reservoir is made of hard plastic material.

- Door handle is made of hard plastic material, which is safe to touch and thermo-insulated.

- Covers are made of aluminum sheet, coated with Epoxy paint.

For additional information, view the full Operations and Maintenance Manual below.

Operation and Maintenance Manual

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.