SARS Covid19 Cultivates Sterilization Process Changes Leave a comment

To destroy bacteria-like viruses and spores, many sterilization methods both physical and chemical have been tested over time with their results being meticulously documented. Each of these methods and their subsequent devices all fall under the standards and regulations of organizations like the CE Medical and FDA. The most common method used is sterilization through steam under pressure. With this process at the end of each sterilization cycle, each instrument placed in the sterilization machine will have been thoroughly sterilized.

Unfortunately, over time microorganisms mutate and build resistance to disinfection and sterilization. Their decreased resistance and the thermal death times of individual vegetative states will vary depending upon the type of microorganism. Because of these changes, it is always necessary to continually test, monitor, and adjust sterilization processes and procedures to maintain the optimum results needed for the eradication of these viruses and spores. And if you just want to talk to someone, call our Free Tech Support at 704-966-1650 Option 3.

What is the Problem With Current Sterilization?

It’s not that current sterilization procedures are bad. The problem is that some microorganisms are more stable and harder to eradicate than others. It is also an ever-changing playing field because of the innate ability of microorganisms to change. And with those changes weaker microorganisms become more stable making them stronger, more resistant, and more difficult to eradicate.

How is SARS Covid19 So Different?

The current epidemic has shown that the virus is already extremely stable. And though there is no documented information on the survival of the Covid19 virus as of yet, studies with related viruses have shown that there are similarities between the current Covid19 and the SARS Corona virus of 2003. In fact the two are about 80% identical as it stands with Covid19’s current genome sequence.¹

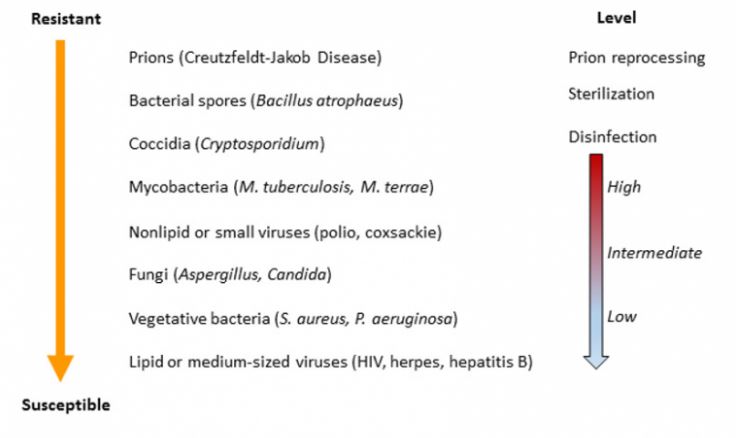

The following illustration displays the decreasing order in which microorganisms resist sterilization, disinfection, etc., and their level from high to low. While the table shows the thermic death times of microorganisms within a vegetative state.²˒³

| Microbial Type | Temperature | Time [min] |

|---|---|---|

| Non-Spore-Forming Bacteria | 58°C | 28 |

| Non-Spore-Forming Bacteria | 61°C | 18 |

| Vegetative Stage of Spore-Forming Bacteria | 58°C | 19 |

| Fungal Spores | 76°C | 22 |

| Yeasts | 59°C | 19 |

| Viruses-- Non-Enveloped | 57°C | 29 |

| Viruses-- Enveloped | 54°C | 22 |

| Protozoan Trophozoites | 46°C | 16 |

| Protozoan Cysts | 60°C | 6 |

| Worm Eggs | 54°C | 3 |

| Worm Larvae | 60°C | 10 |

Room Temperature and Virus Survival Numbers

A test of SARS and other proxy viruses’ survival was conducted and produced the following results. Beginning at 20°C, substances like body fluids, sputum, and serum, as well as surfaces could survive for 4 days. Respiratory secretions lasted 4-5 days⁴, drying on porous material (papers) 4 days⁵, and dried on plastic materials 6-9 days. Amazingly the survival time increased up to 4 weeks when the temperature was dropped to 4° C.

Elevated Virus Survival Numbers

Positive results were found when increasing the test temperatures. The virus survival time at 56°C was 90 minutes, at 67°C it was 60 minutes, and at 75°C the time drastically decreased to just 30 minutes. The studies proved that the kill time drastically reduced as the temperature rose at varying degrees. Following these parameters, it is fair to deduce that by raising the temperature to 100°C, the time to kill the virus would only be about 5-7 minutes.

Tuttnauer’s Findings and Fix

Using all of the results gathered by the thermal kill time studies, Tuttnauer ( a world leading autoclave sterilizer manufacturer) recommends using a pre-heating cycle at 100°C for 7 minutes prior to the regular sterilization cycle to inactivate the SARS-CoV-2 virus.

Due to these findings, Tuttnauer has added an extra pre-heating stage of 103°C for 15 minutes to minimize the risk of airborne contaminations that can develop during the first stage of some sterilization cycles. Because these risks become even more prevalent the closer you are to the autoclave, the pre-heating stage allows no air exhaustion into the surrounding environment. When this pre-heating stage has finished the rest of the sterilization process proceeds as normal.

See the Tuttnauer Elara 11 Pre Post-Vacuum Class B Sterilizer Here.

References

- Geler, C.; Varbanov, M.; Duval, RE.; “Human coronaviruses: insights into environmental resistance and its influence on the development of new antiseptic strategies”, Viruses. 2012 Nov 12;4(11):3044-68. doi: 10.3390/v4113044.

- Decreasing order of resistance of microorganisms to disinfection and sterilization and the level of disinfection or sterilization, Centers for Disease Control and Prevention, National Center for Emerging and Zoonotic Infectious Diseases (NCEZID), Division of Healthcare. CDC guideline for disinfection and sterilization in healthcare facilities, 2008

- Average Thermal Death Times of Vegetative Stages of Microorganisms. Talaro, K.P.; Chess, B.; “Foundations in Microbiology”, Physical and Chemical Agents for Microbial Control, 7th Ed., Chap. 11, The McGraw-Hill Companies, Inc., 2008

- Casanova, LM; Jeon, S.; Rutala, WA; Weber, DJ; Sobsey, MD; “Effects of air temperature and relative humidity on coronavirus survival on surfaces”, Appl Environ Microbiol. 2010 May;76(9):2712-7. doi: 10.1128/AEM.02291-09. Epub 2010 Mar 12.

- Heat inactivation of SARS-CoV-2. Eitan Israeli, heat process inactivation recommendation, Israeli Biohazard Ltd., recommendation letter, 2020.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.