VistaCool V7502 Operation Guide Leave a comment

In this article, we’ll tell you how to operate your VistaCool V7502. And if you just want to talk to someone for any questions you may have, call our Free Tech Support at 704-966-1650 Option 3.

Starting and Using the System

- Turn on the main water supply and check for leaks.

- Slowly open the inline water supply valve fully and check for leaks.

- Prime the system by inserting a small screwdriver in the view port hole on the brass stem of the thermal regulator on top of the tank and pushing up on the water valve piston. The system is primed when water can be seen leaving the 1/2” overflow fitting on the tank and running to the drain adapter.

- Set the water tank in an elevated position above the drain connection as described above to ensure proper drain flow. The tank may need to be set securely on blocks to achieve the proper height.

- After making all connections, make sure the water coolant valve is fully open. Check again for leaks, then run three consecutive autoclave cycles to ensure everything is working properly.

Because VistaCool is a low-maintenance alternative to using condenser/waste bottles and tanks, once it is properly installed and primed it will function without operator input. Beyond periodic visual inspections of the tubing, there is nothing that users must do to ensure continued and safe operation.

Connecting to a Midmark M3

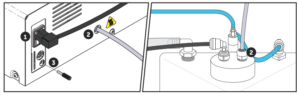

- Shut off the M3 and disconnect its power cord

- Connect the high-temperture Teflon tubing provided to the back of the M3 as shown, and also to the high-temperature Kynar inlet on the VistaCool manifold

- Insert the 35mm mono plug provided with the VistaCool into the back of the M3 to override the flow display alert function

- Reconnect the M3’s power cord and resume operation

Important Midmark Compatibility Information

- VistaCool systems can be installed on Midmark M9 & M11 units, but an adapter kit (S7560) is required. Only M9, M9D, M11 and M11D (-02X, -03X) units with green displays can be connected to VistaCool. First generation models with red displays (-0XX) cannot be connected to VistaCool.

- While approved for use with the Midmark M9 units, the single-unit VistaCool (V7501) should not be used with Midmark M11 units. The double-unit VistaCool (V7502) is capable of handling one or two M11 units (or any two compatible autoclaves).

Complete installation instructions for the M9 & M11 units are included with the S7560 adapter kit.

Maintenance

The VistaCool direct-to-drain thermal reduction systems for autoclaves have been designed to require virtually no maintenance. However, it’s recommended that operators periodically verify that the tubing and connections remain leak-free, are free of mineral deposits or debris, and are not compromised in any way. The system includes several fail-safe devices designed to stop the flow of exhaust water from the autoclave in the event of a problem. Here are a few recommended procedures:

Operator

Every 6 months:

- Check clear tubing for mineral deposits.

- Visually inspect all connections to ensure there are no leaks.

Technician

Annually:

- Visually inspect system for leaks.

- Manually cycle the water valve piston. Push upward on the piston to make certain water runs to out the coolant overflow line to the drain.

Troubleshooting

Technician

System is not draining:

- Ensure water supply valve is in the ON position.

- Check for blockages in the tubing.

- Check water level in tank.

Autoclave is displaying a cycle fault:

- Exhaust port line is blocked. Check for kinks in tubing from the autoclave to the VistaCool manifold.

- Check that water is running from the tank coolant overflow line to the drain adapter.

- Make certain water supply valve is on. If there is no water to cool the coil(s) in the tank, the inline thermal sensor located in the condensate line will respond by closing the pathway to alert you of the problem and protect the plumbing from steam.

The black condensate line appears to be blocked:

- The inline thermal sensor has been activated, blocking condensate flow to the drain, caused by a lack of coolant water in the tank that overheated the condensate. Overheated condensate will cause the wax motor to expand, closing the outlet. To reset the inline sensor and enable flow to resume, allow the system to rest and cool naturally. The inline sensor’s wax-motor piston will retract, opening the outlet port.

Water tank is bloated:

- Raise the water tank so the top of the tank is above the drain point.

Water leaking under the counter:

- Check all tubing and fitting connections.

- Push in on all push-to-connect fittings to ensure the tubing is fully engaged in the fitting “O” ring.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

The VistaCool V7502 is available to purchase here.

Any other available parts for the unit are also available here.