SciCan HYDRIM L110W G4 Maintenance Guide

We’ve recently talked about the SciCan HYDRIM L110W G4 Instrument Washer, and showed you how to install it, operate it, and walked through cycle data storage and retrieval. And now we’re going to continue our guide through its processes with the Hydrim L110W G4 Maintenance Guide. These instructions come from the manufacturers themselves. For proper data management and retrieval when using your Hydrim L110W G4. And if you have any questions about this or anything else, you can call us at 704-966-1650, option 3 for our free tech support.

through its processes with the Hydrim L110W G4 Maintenance Guide. These instructions come from the manufacturers themselves. For proper data management and retrieval when using your Hydrim L110W G4. And if you have any questions about this or anything else, you can call us at 704-966-1650, option 3 for our free tech support.

Maintenance

Replacing the HIP Cleaning Solution

The HYDRIM L110w G4 uses a 3.8L / 1 gallon container of HIP Cleaning Solution (Part number CS-HIPL). Use only the recommended cleaning solution and read the MSDS before inserting into the unit.

HIP cleaning solution is used in dilute form as a detergent for the cleaning of surgical instruments in the HYDRIM washer. It is a colorless and almost odorless liquid that is completely soluble in water. Some precautions must be taken to safely handle this chemical. For more information, see the installation guide, section “Handling and Installing the HIP cleaning solution.”

NOTE: To avoid spillage, replace the solution container only when the message appears and be sure to wear gloves.

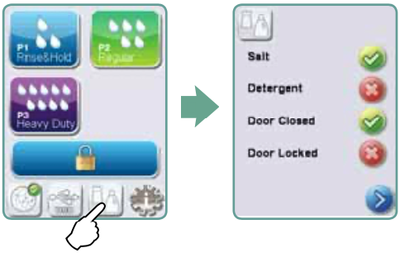

When a red X appears on the water softener/detergent icon. Press on the icon to determine if the problem is with the water softener or cleaning solution level. If the cleaning solution must be replaced, a red X will appear next to it.

To order additional HIP Cleaning Solution, contact your local dealer. When the message “no detergent” appears on the screen, the cleaning solution container is empty and is in need of changing. To avoid spillage, replace the solution container only when the message appears and be sure to wear gloves.

NOTE: Each cleaning solution container will last approximately 30 cycles, depending on which cycles are used.

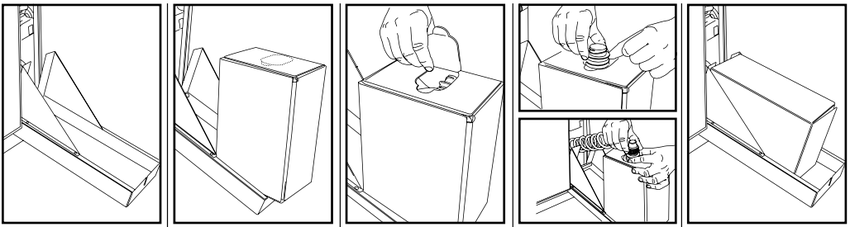

To replace the cleaning solution container, follow these steps:

- Turn the power switch OFF.

- Open the cleaning solution door.

- Disconnect the cleaning solution connector. Remove any dried chemical by immersing the connector in a cup of water.

- Remove the empty cleaning solution container and discard or recycle.

- Connect new container and insert into the cleaning solution compartment. Follow the instructions printed on each cleaning solution container.

- Close the door.

- Turn the power switch ON

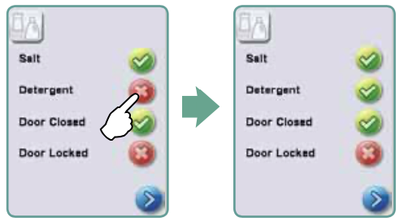

To prime the cleaning solution dosing pump, press the water softener/detergent icon on the main screen. In the water softener/detergent screen, press the red X next to “Detergent”. The unit will prime the dosing system and a green check mark will appear in place of the red X when it is ready for use.

To prime the cleaning solution dosing pump, press the water softener/detergent icon on the main screen. In the water softener/detergent screen, press the red X next to “Detergent”. The unit will prime the dosing system and a green check mark will appear in place of the red X when it is ready for use.

NOTE: The system can also be primed by simply starting a cycle and selecting “Detergent Replaced”, when prompted.

Refilling the Water Softening Salt Reservoir

When a red X appears on the detergent and water softener level indicator, press on the icon to determine if the problem lies with the water softener or cleaning solution level. If the water softener must be refilled, follow these steps:

To fill the salt reservoir, follow these steps:

1.) Unscrew the salt container lid.

2.) Fill the salt container to the top (maximum 1 kg / 2.2 lbs.)

3.) Screw the salt container lid on tightly.

4.) Run a complete cycle, with no instruments.

Cleaning the Hydrim L110W G4

To clean outer surfaces and the decal covering the touchscreen, use a soft cloth moistened with soap and water or a surface disinfectant. Do not use harsh cleaning chemicals.

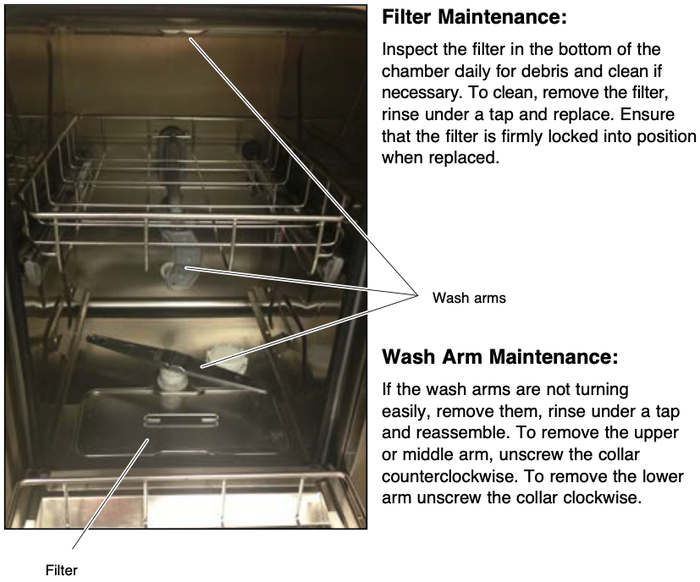

Filter and Wash Arm Maintenance

Preparing the Unit for Shipping

Preparing the Unit for Shipping

If preparing the unit for transport or storage, waste water should be removed from the sump. Waste water in the unit may contain biological contaminants. From the Setup menu, select the Prepare for Shipping function.

Use a mechanical means or absorbent material to siphon the contents from the sump. Wear disposable rubber gloves. Dispose of absorbent material according to biological waste disposal regulations.

Annual Maintenance

If the message “Preventative Maintenance Required. Call for Service” appears, the annual maintenance is required. To continue using the HYDRIM, press OK. Call for service as soon as possible. The annual maintenance should be done after 365 days have elapsed since the initial installation or since the last service call was performed.

When Who What Tests

Daily tests and checks By the user • door lock check

• wash arm rotation check

• door seal check

• load carrier check

• check and clean chamber filters

• visual examination of each load for residual soil.

Annually By a SciCan-approved technician • Annual maintenance schedule as outlined in the service manual

Bi-Annually By a SciCan-approved technician • Re-validation if required by local regulations.

To ensure that the ongoing efficacy of the machine is assured, SciCan recommends that the following periodic testing protocols are observed.

Important Notes

This document outlines the minimum requirements to ensure that the equipment performs to specification. In some regions, local/national guidance documents may require additional testing. Please contact your dealer or local medical authorities for details.

Installation, commissioning, annual servicing MUST be undertaken by SciCan approved technicians. Failure to maintain this equipment may invalidate the results of the following testing regime.

Tests To Be Performed By The User

Door lock check

This test is to ensure that the door cannot be opened while a cycle is running or a cycle will not start with the door open. To check that these features are working correctly, attempt to open the door using the handle immediately after a cycle has started. Caution – DO NOT attempt this when the wash arms are rotating and/or the water is above ambient temperature. The door should not open. When you attempt to start a cycle with the door open, the cycle should not start. If the unit fails this test, stop using it immediately and call your dealer for technical service.

Wash arm rotation check

Run a P1 cycle and check that wash arms are rotating. If wash arms are not rotating, remove, visually check and clean as described in section “Filter and Wash Arm Maintenance.”

Door seal check

Visually check the door seal for debris or wear. If the seal is worn or damaged, call your dealer for technical service.

Load carrier check

Visually check load carriers (trolleys) for wear and tear, damage and that the runners move freely over their full range.

Chamber filter check

Remove, visually check and clean as described in section “Filter and Wash Arm Maintenance.”

Load check

Visually inspect each load for residual soil. Washers are designed to ensure that the surfaces of instruments are free from debris that may compromise the sterilization process. A visual check of the instruments processed in each load should be undertaken prior to sterilization to ensure that no residual debris is present on the instrument.

If debris is still apparent, the instrument should not be considered clean and should be reprocessed through the HYDRIM again prior to sterilization.

Note: Some set-able materials such as cements, amalgam, and composites, if set on the instrument will not be removed in a HYDRIM. If these materials are noticed on the instrument then abrasive removal may be required.

As always if you have any questions about this process or anything else please feel free to contact us and take advantage of our “FREE TECH SUPPORT.”

We also offer FREE VIRTUAL TECH SUPPORT to “See and Talk” with a “Real Time Live Technician” for any problems you may be in need of help with.

You can also use our “FREE MAINTENANCE PROGRAM”. Take the guesswork and worrying about what unit is due for maintenance and which maintenance cycle it is time for. We will keep track of all your autoclaves and let you know when it’s time for anything.

The SciCan Hydrim L110W G4 Instrument Washer is available on our site here.